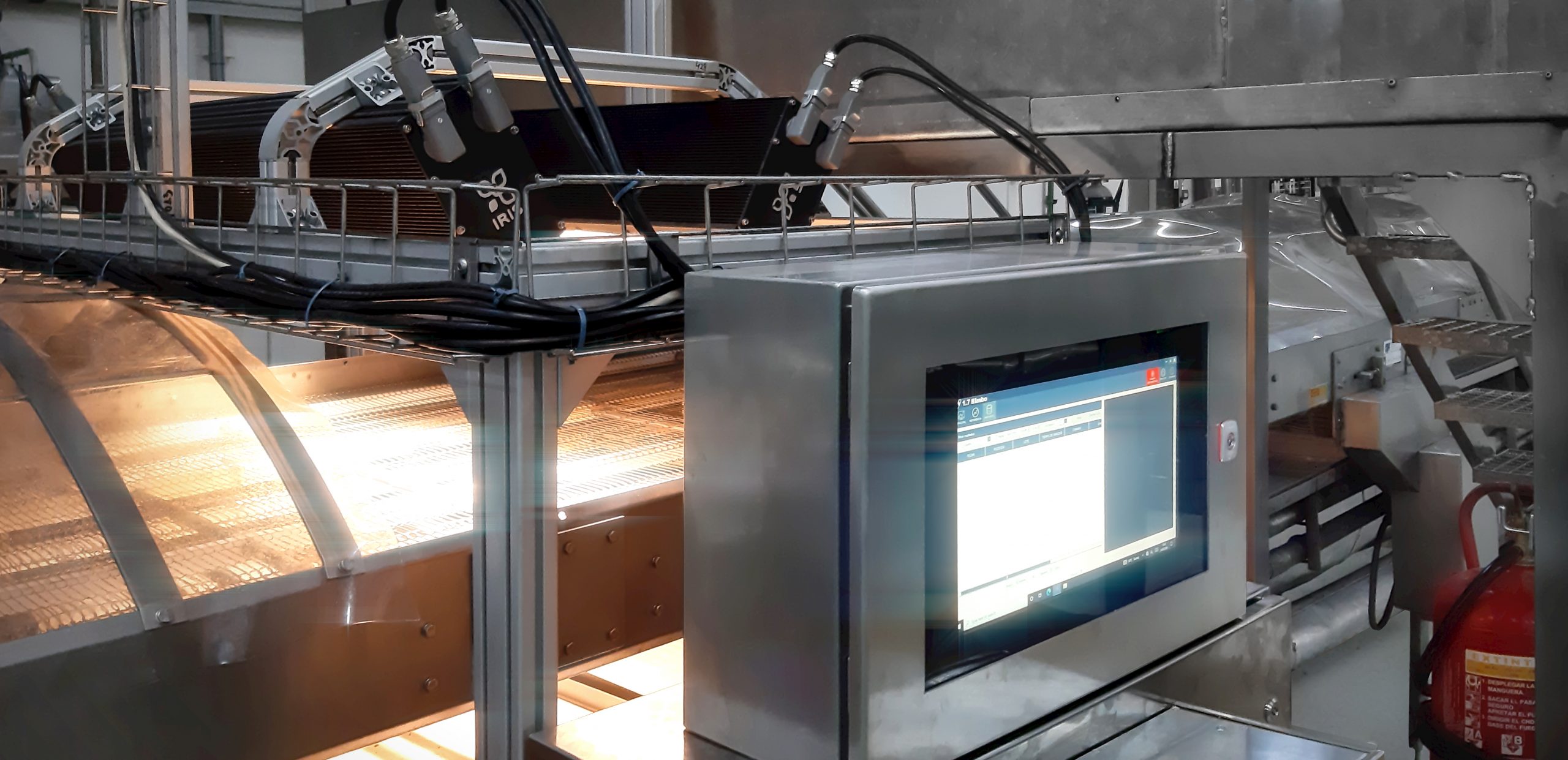

Visum HSI™ - Hyperspectral Imaging System

Spatially resolved chemical vision. Hyperspectral imaging system (HSI) for physical chemical analysis, detection and sorting in real time. Make it perfect.

REQUEST A QUOTEHYPERSPECTRAL IMAGING SYSTEM FOR REAL-TIME MONITORING

VISUM HSI™ is the most robust and versatile Hyperspectral Imaging System (HSI) on the market. It is designed to be integrated into any production line and provides pixel-by-pixel physical chemical information of everything that passes over the conveyor belt.

TURNKEY SOLUTIONS

IRIS Technology is a pioneer in the design of turnkey hyperspectral imaging systems for in-line control of various industrial processes. The NIR or Vis-NIR combination of the Visum HSI™ hyperspectral imaging system allows it to adapt to the characteristics of each product and to the client's needs to perform multiple operations, including foreign body detection, quantitative and qualitative analysis and sorting of food, sorting of organic and inorganic waste, recovery and recycling of plastics, textiles, among other applications, industries and processes.

Main features

- Detection of superficial foreign bodies in the production line (paper, cardboard, rubber, plastics, metals, among others).

- Quantitative and qualitative analysis with spatial distribution of each product unit passing over the conveyor belt.

- Control of homogeneity, distribution and quantity of ingredients desired in each product unit.

- Versatile technology: NIR or Vis-NIR.

- IRIS Technology’s hyperspectral imaging systems adapt to the required belt width and speed without limitations.

- Integrated with all types of PLC, rejection system and SCADA.

- Improvement of quality and safety.

- Brand image protection.

Sectors

Food

- Quantitative and qualitative analysis of each product unit (fats, fibers, proteins, moisture, among others or qualitative parameters such as shape, color and texture), depending on the product.

- Detection of superficial foreign bodies for rejection.

- Product homogenization.

- Product or recipe optimization.

Recycling / Circular Economy

- Characterization, quantification and classification of polymers.

- Sorting of plastics in recycling.

- Recovery of multilayer plastics.

- Monitoring and sorting of organic and inorganic waste.

Woodworking

- Moisture monitoring of particleboards in the impregnation line.

- Curing factor classification of wood boards.

- Quantification of wood chips flow for process control.

- Quantification or classification of resins.

- Detection of anomalies, defects and foreign bodies.

- Read more about NIR applications in the wood industry.

Acquisition mode

Push-broom (the field-of-view is scanned line by line)

Spectral range

900 -1700 nm / 400-1000 nm

Number of spectral channels

>256

Number of pixels / line

>320

Acquisition speed

> 300 lines/s

Belt speed

>30 m/min

Acquisition geometry

Diffuse reflectance

Inspection area

No limitations

Ingress protection

IP69

Basic connectivity

Ethernet (TCP/IP)

User interface

External PC-based

Data output

Ethernet (TCP/IP), Modbus, Profinet, Profibus

Operation mode

Slave / Continuous