Visum Palm™ - Handheld NIR analyzer

Portable NIR analyzer, handheld and benchtop, AI-assisted. For use in the field, production process, or laboratory. The most complete, versatile, and intelligent NIR analyzer on the market.

REQUEST A QUOTEHANDHELD NIR ANALYZER FOR REAL-TIME MULTIPLE PARAMETER DETERMINATION

Visum Palm™ is a user-friendly, self-contained, handheld NIR and benchtop analyzer designed for real-time analysis of the chemical composition of a wide variety of materials and mixtures. Available in two versions: Visum Palm™ and Visum Palm GxP™, the latter incorporating embedded software that ensures compliance with the highest industry standards: CFR 21 Part 11, GMP, GAMP 5, USP , and European Pharmacopoeia (Ph. Eur.). A solution designed for regulated environments demanding maximum traceability, precision and security.

Visum Palm™: The versatile handheld NIR analyzer for real laboratory-quality results

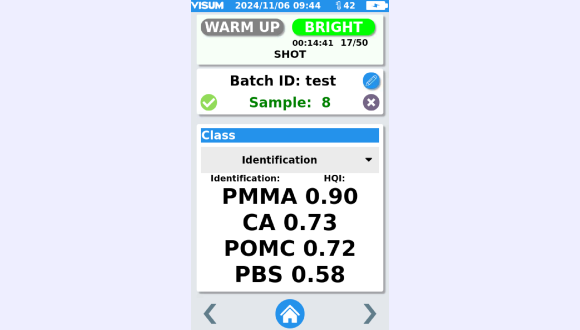

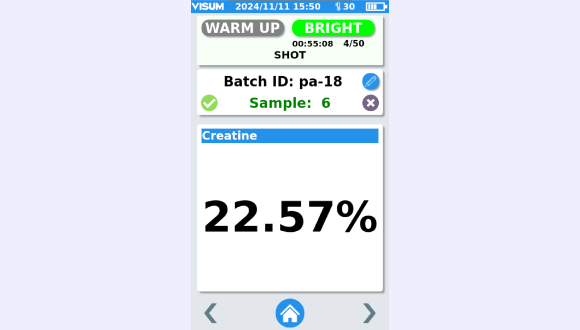

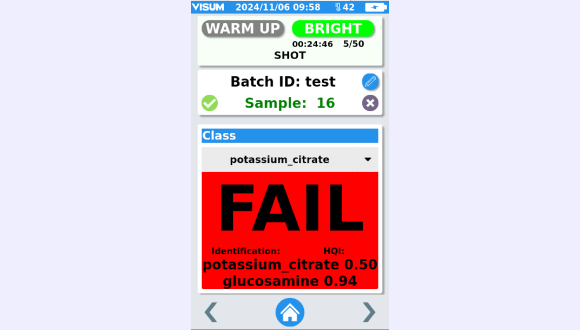

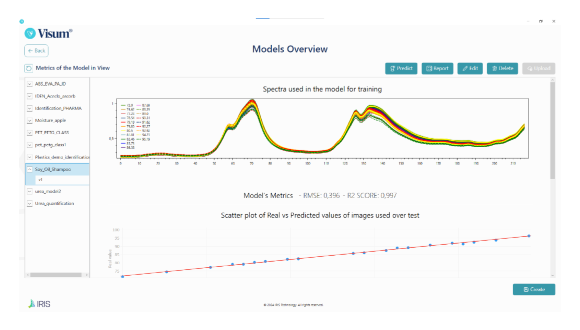

The Visum Palm™ handheld NIR analyzer is the only device in its category offering true dual functionality, allowing use both as a handheld device and in benchtop mode, with full operational autonomy, as it does not require any external device to operate. Visum Palm™ stands out for its high spectral resolution, low instrumental noise level, and a highly efficient optical collection design, making it an ideal solution for critical applications requiring precision and repeatability. Thanks to the Visum Master™ PC software, any analyst can easily develop calibrations and methods without the need for advanced technical knowledge with its automatic Model Builder. Applications of the Visum Palm™ handheld NIR analyzer span a wide variety of industries and sectors, including the analysis of agricultural raw materials, forages and mixtures, animal feed products, as well as the identification of plastics and textiles, among others. In its GxP version, Visum Palm™ is especially useful in regulated environments, such as the pharmaceutical industry, enabling raw material identification (RMID), loss-on-drying (LOD) analysis, and quantitative assays of APIs and excipients, even in product release applications.

Main features

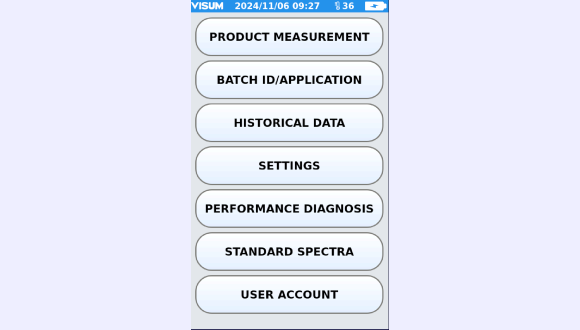

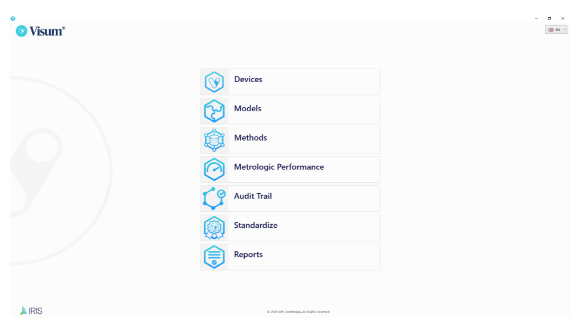

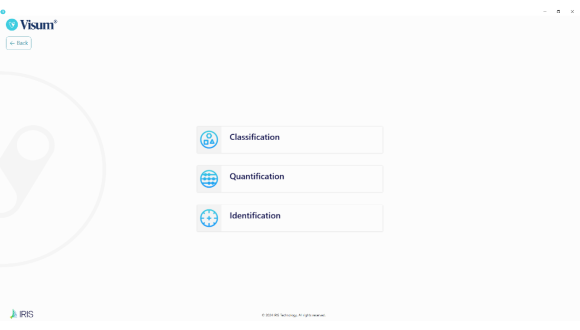

The device allows performing all key functions directly from its interface: batch identification or barcode reading, analysis selection, results and spectra visualization, access to measurement histories, configuration adjustments and user management.

The GxP version incorporates advanced features such as Audit Trail, electronic signature, operation validation, instrumental qualification assisted by reflectance standards, and specific configurations for CFR and GMP compliance.

By simply inputting spectra and reference data (quantitative or qualitative), users can generate robust calibrations without prior knowledge in spectroscopy.

Visum Master™ marks the beginning of a new era in accessing and leveraging NIR technology, democratizing its use and eliminating technical barriers.

It includes benchtop sample holders for granules, powders, and solids, as well as accessories for liquids, including reusable or disposable cuvette holders compatible with spectrophotometry and adjustable optical pathlength.

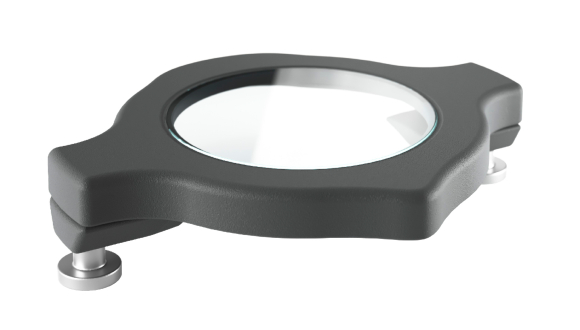

It also features an optical flattener designed for direct analysis through translucent packaging, without the need to open or handle the sample.

Why choose the handheld NIR analyzer Visum Palm™?

-

Autonomous System: The portable handheld NIR analyzer is fully integrated, with a built-in computer and software, eliminating the need for external devices.

-

Dual-Function Use: The only portable NIR analyzer that can easily switch between handheld and benchtop modes, adapting to various analytical needs in different locations.

-

Highest Spectral Resolution: Offers a resolution of 5 nm with 256 spectral channels, providing precise and reliable real-time data.

-

Superior Signal-to-Noise Ratio: With a ratio of 4500:1, it significantly surpasses other portable analyzers on the market and USP requirements in regulated environments.

-

AI-Assisted Software: The Visum Master™ Model Builder allows users to develop and update NIR calibrations and methods without the need for technical knowledge.

-

Regulatory Compliance: The GxP version complies with CFR 21 Part 11, USP 1119, and Ph. Eur. 2.2.40 regulations, as well as GMP and GAMP 5 guidelines. Ideal for regulated environments.

SENSOR

InGaAs Photodiode array

SPECTRAL CHANNELS

256

SPECTRAL RANGE

900 - 1700 nm

WAVELENGTH PRECISION

<1 nm

USE MODE

Handheld and benchtop analyzer

MEASUREMENT AREA

10 mm

LIGHTING AREA OF THE SAMPLE

50 mm

LAMP

Halogen

TIME OF ONE MEASUREMENT

3 seconds

TYPICAL ACQUISITION TIME FOR A SINGLE SPECTRUM

5 ms

SPECTRAL RESOLUTION (↓ nm = ↑ spectral resolution)

5 nm

SIGNAL-TO-NOISE RATIO

4500:1

ACQUISITION GEOMETRY

Diffuse reflectance. Transflectance and transmittance with optional accessory on request

WEIGHT

1.8 kg

IP PROTECTION

IP54 - IP66 (optical aperture)

POWER SUPPLY

Rechargeable and replaceable battery. Charger (220 VAC) integrated into the device

LIFETIME OF THE LIGHT SOURCE

Up to 2 years standard use or 4000 h

BATTERY LIFE

Up to 5 hours. Spare battery and external charger optional.

INTEGRATED COMPUTER

Dual-core ARM® A7

BASIC CONNECTIVITY

Ethernet (TCP/IP) / Wi-Fi

USER INTERFACE

Integrated 5.3" resistive touch screen and manual trigger for spectrum acquisition

EMBEDDED SOFTWARE

Visum®

CFR 21 PART 11 EMBEDDED SOFTWARE

Available in Visum Palm GxP™. Also complies with USP 1119 and PE 2.2.40.

EXTERNAL SOFTWARE FOR PC

Visum Master™ Windows 10 or higher operating system. Recommended requirements: Intel i5, 16 GB RAM, 120 GB storage, 1366x768 resolution.

BARCODE SCANNER

Yes. Optional on request.