Ayudamos a la industria a integrar soluciones de análisis físico químico en tiempo real para optimizar el control de calidad y de procesos.

EQUIPOS PARA EL CONTROL DE PROCESOS Y CALIDAD EN TIEMPO REAL

Bajo la marca Visum® fabricamos soluciones integrales para mejorar la calidad y controlar procesos productivos de una gran variedad de industrias. Nuestros sistemas a base de espectroscopía NIR, imágenes hiperespectrales, espectroscopía Raman y Visión Artificial ofrecen información y resultados en tiempo real. Visum® trae el laboratorio a la línea de producción.

Tecnología

Espectroscopía en línea

Combinamos tecnología NIRS (Near-Infrared Spectroscopy), Imágenes Hiperespectrales (HSI) y espectroscopía Raman en tiempo real, entre otras técnicas fotónicas como UV y fluorescencia con herramientas de inteligencia artificial y software para el desarrollo de soluciones para el análisis y clasificación de alimentos, granos, de plásticos, residuos orgánicos e inorgánicos, paneles de madera, productos farmacéuticos, químicos, cosméticos, entre una gran variedad de materiales y mezclas.

Visión Artificial & Deep Learning

Empleamos nuestro conocimiento en óptica, software e ingeniería para el desarrollo de sistemas de visión artificial y redes neuronales -o deep learning- para distinguir y clasificar anomalías, caracteres y variaciones naturales en patrones complejos. Nuestros sistemas de visión artificial se emplean para el control y análisis de defectos en granos, frutos secos, pescados, etiquetado, envasado, entre las aplicaciones más populares de la tecnología.

Beneficios

- Monitorización de parámetros físico químicos en tiempo real.

- De uso industrial y no requiere personal especializado.

- Posibilidad de analizar múltiples parámetros en simultáneo.

- Ahorro de tiempos de análisis de laboratorio, insumos o inspección visual.

- Información en tiempo real para rectificar procesos y optimizar la toma de decisiones.

- Detección de cuerpos extraños superficiales.

- Reducción de pérdidas, reclamos y/o devoluciones.

SOLUCIONES POR INDUSTRIA

Error: Formulario de contacto no encontrado.

Error: Formulario de contacto no encontrado.

Error: Formulario de contacto no encontrado.

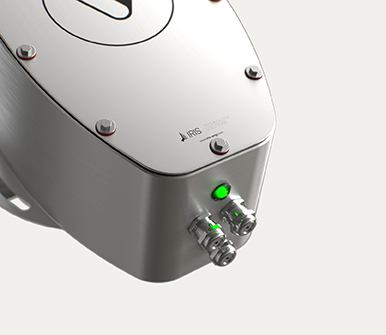

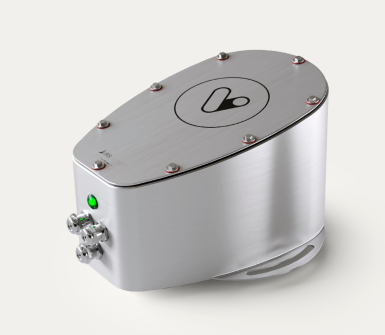

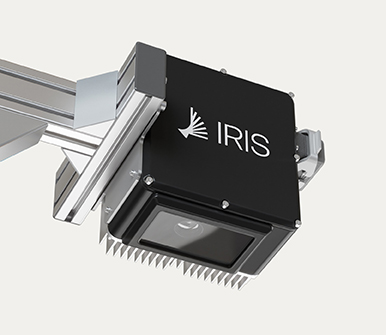

NUESTROS DISPOSITIVOS

Soluciones no destructivas, precisas y en tiempo real. Conozca nuestra línea de dispositivos Visum®.

LO QUE NUESTROS CLIENTES DICEN DE IRIS