Raman Process Analyzer for Real-Time Rapamycin Monitoring: Results Comparable to HPLC

Raman Process Analyzer for Real-Time Rapamycin Monitoring: Results Comparable to HPLC

What is the best handheld NIR analyzer on the market? A comparison between Visum Palm™ and other portable NIR devices

What is the best handheld NIR analyzer on the market? A comparison between Visum Palm™ and other portable NIR devices

Visum Palm GxP: The New NIR Analyzer for Pharmaceutical

Visum Palm GxP: The New NIR Analyzer for Pharmaceutical

The Visum Palm GxP is the latest NIR analyzer for pharmaceutical applications developed by IRIS Technology Solutions. This portable, robust, and fully validated device redefines how the pharmaceutical industry performs quality control, batch release, and raw material verification, delivering speed, precision, and regulatory compliance in one instrument.

With a spectral range of 900 to 1700 nm and a signal-to-noise ratio of 4500:1, the Visum Palm GxP ensures reliable results in every measurement. Its self-contained architecture and embedded software make it the ideal tool for GMP environments, whether in the laboratory, production area, or warehouse.

Why Choose a NIR Analyzer for Pharmaceutical Applications

Near-Infrared (NIR) spectroscopy has become a cornerstone technology for the pharmaceutical industry. It enables non-destructive sample analysis, requires no preparation, and delivers results in seconds. A NIR analyzer for pharmaceutical processes provides clear advantages:

-

Rapid identification of raw materials, even through transparent packaging.

-

Real-time, in-line process control.

-

Evaluation of content uniformity and moisture (loss-on-drying).

-

Faster batch release, reducing QC lead times.

The Visum Palm GxP takes these benefits further by combining premium hardware with advanced software tools, meeting the most demanding requirements of international regulations.

Key Features of the Visum Palm GxP: Technical Specifications

Developed specifically as a NIR analyzer for pharmaceutical use, the Visum Palm GxP complies with 21 CFR Part 11, USP <1119>, Ph. Eur. <2.2.40>, and GAMP 5 standards. Notable specifications include:

-

Spectral range: 900–1700 nm

-

Design: self-contained analyzer (built-in computer, software and touchscreen), eliminating the need for an external PC, tablet, or mobile device. This simplifies daily operation and qualification process in GMP environments.

-

Spectral resolution: 5 nm with 256 channels — the highest resolution available among portable NIR analyzers.

-

Signal-to-noise ratio: 4500:1 (almost twice the USP <1119> standard).

-

Measurement area: 10 mm with 50 mm illumination.

-

Measurement time: 3 seconds.

-

Geometry: diffuse reflectance; transflectance with optional accessory.

-

Weight: 1.8 kg, IP54–IP66 protection.

-

Battery life: up to 5 hours, rechargeable and replaceable.

These features guarantee analytical reliability, even under demanding production conditions.

Regulatory Compliance and Data Security

The Visum Palm GxP is designed to be the most comprehensive portable NIR analyzer for pharmaceutical environments, offering advanced functionality for GMP compliance, particularly with FDA 21 CFR Part 11:

-

Full audit trail with complete traceability of operations and results (who did what and when). Includes a device audit trail and a results-only audit trail.

-

Daily instrument diagnostics with alarms for operating status.

-

Role-based access control (Analyst, Supervisor, User Manager) with privileges preconfigured by the manufacturer.

-

Electronic signatures with dual authentication (Analyst and Supervisor).

-

Secure password policies, automatic session logout, and recovery functions.

-

Safe backup and restoration of data.

These capabilities guarantee data integrity and simplify regulatory audits.

Visum Master™ GMP Software: Intelligence Applied to NIR

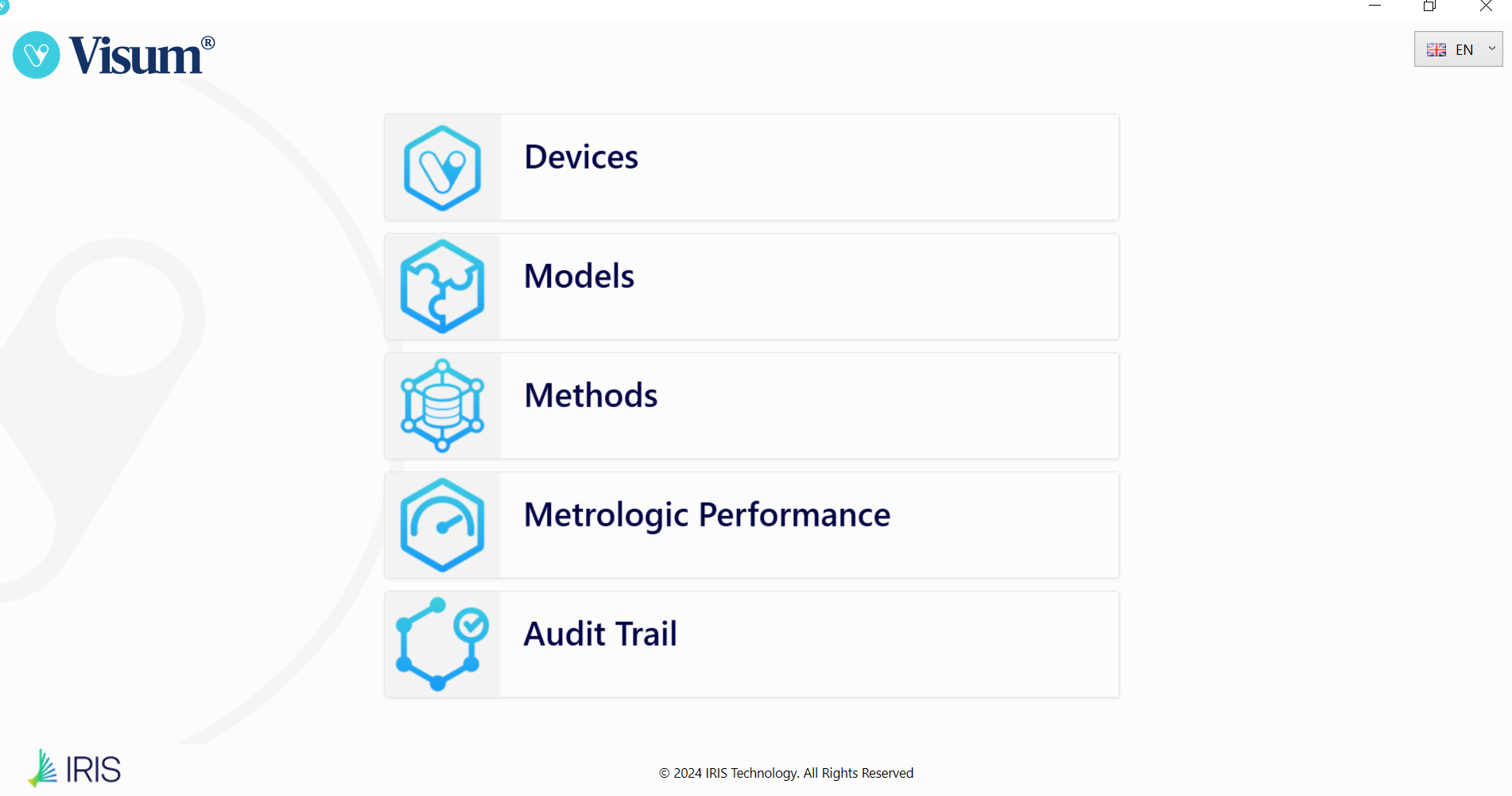

A critical component of the NIR analyzer for pharmaceutical Visum Palm GxP is its software ecosystem:

-

Visum Master™ GMP enables the creation of identification libraries and quantitative models without advanced chemometrics expertise. It is the only software on the market that automates NIR library development thanks to its built-in Model Builder.

-

Automatically generates complete reports compliant with ICH Q2(R2), supporting both internal and external validations.

-

Includes automatic diagnostics, user management, and tools for wavelength accuracy, noise, and photometric linearity verification according to USP, Ph. Eur., and JP18.

As a Class 4 software package, Visum Master™ simplifies qualification tasks, making the deployment of a NIR analyzer for pharmaceutical operations faster and more efficient.

Accessories to Expand the Potential of the NIR Analyzer for Pharmaceutical Use

The Visum Palm GxP comes with a full range of accessories designed for laboratory and production needs:

-

Benchtop sample holders for solids, granules, and powders.

-

Cuvette holders (1–10 mm) for liquid analysis in transflectance mode, compatible with disposable or reusable cuvettes, open or sealed.

-

Mini sampler and surface flattener.

-

Optional barcode reader for streamlined traceability.

These accessories enable the NIR analyzer for pharmaceutical applications to handle diverse sample formats — from fine powders to liquids or granules — and to switch seamlessly between handheld and benchtop configurations.

Use Cases for the NIR Analyzer for Pharmaceutical Visum Palm GxP

The NIR analyzer for pharmaceutical Visum Palm GxP offers a wide range of applications across the industry, from raw material reception to final batch release. Its portability, validated software, and exceptional signal-to-noise ratio make it indispensable for meeting GMP standards and streamlining workflows. Let’s see the most relevant nearinfrared spectroscopy applications in pharmaceuticals and life sciences industries:

Raw Material Identification

The Visum Palm GxP allows operators to identify and verify active ingredients and excipients in seconds, even without opening translucent or transparent packaging. This reduces QC time, minimizes cross-contamination risk, and lowers human error during incoming inspections.

NIR technology is particularly effective for organic raw materials, and it can also verify inorganic substances when hydrated, hygroscopic, or in solution. Compared to other techniques, a NIR analyzer for pharmaceutical use is faster, more economical, and safer than handheld Raman analyzers, which struggle with pure ionic compounds (NaCl, KCl, HCl) or substances that fluoresce.

The Visum Palm GxP simplifies the development of robust identification libraries, accommodating variations between suppliers and batches while ensuring full traceability and compliance with pharmacopeias like USP and Ph. Eur. As a result, the NIR analyzer for pharmaceutical becomes the first line of defense for supply chain integrity.

Content Uniformity and Quantification

With its high signal-to-noise ratio (4500:1) and 5 nm resolution, the Visum Palm GxP is an ideal NIR analyzer for pharmaceutical quantification. It supports the development of automated quantitative models to assess content uniformity in tablets, capsules, granules, emulsions, liquids, or powder blends, as well as the exact concentration of APIs and excipients.

The NIR analyzer for pharmaceutical allows automated model training and provides advanced tools and metrics for evaluating result quality, even offline with validation spectra. Automatic reporting follows the guidelines of ICH Q2(R2) – Validation of Analytical Procedures, reducing the time and effort required for method documentation.

Real-Time Process Control

As a NIR analyzer for pharmaceutical manufacturing, the Visum Palm GxP can be installed at critical production points or used in the lab to monitor essential variables:

-

Residual moisture in granules or powders during drying.

-

Drying progress in fluid beds.

-

Coating thickness on microgranules or tablets.

-

Blend uniformity before compression or encapsulation.

Information provided by the NIR analyzer for pharmaceutical enables near real-time process adjustments, improving product quality and reducing the risk of out-of-specification batches. This Process Analytical Technology (PAT) approach strengthens statistical process control and supports more robust manufacturing.

Batch Release

The Visum Palm GxP accelerates batch release thanks to its fast, non-destructive analysis. By delivering analytical results in seconds without compromising product integrity, the NIR analyzer for pharmaceutical enables immediate decisions on batch acceptance or rejection. This shortens QC cycles and enhances overall plant efficiency.

Because it is portable, the NIR analyzer for pharmaceutical can analyze batches in storage, on packaging lines, or in the lab, adapting to any scenario without sacrificing reliability or regulatory compliance.

Research and Development

Beyond routine QC, the Visum Palm GxP is an excellent NIR analyzer for pharmaceutical R&D environments. It supports excipient compatibility studies, formulation optimization, and stability testing, providing fast insights into the behavior of new products while consuming minimal material. This makes it ideal for pilot projects and scaling new dosage forms.

Advantages over Other Portable NIR Analyzers

Unlike generic devices, the Visum Palm GxP is designed exclusively as a NIR analyzer for pharmaceutical workflows. Its key advantages include:

-

Built-in validation and regulatory compliance, facilitating qualifications and validations from the start.

-

Optimal performance in GMP environments, with complete auditing and traceability.

-

Rugged hardware, ideal for warehouses, production areas, or laboratories.

-

Dual functionality: handheld and benchtop operation in one instrument.

-

Intuitive software for model building, library management, and data control.

These qualities make the Visum Palm GxP the safest choice for organizations seeking a NIR analyzer for pharmaceutical tasks with full support.

Conclusion

The Visum Palm GxP is far more than just a NIR analyzer for pharmaceutical testing. It is an integrated solution for quality control, raw material identification, and process optimization in GMP environments. Its portable, self-contained design, dual functionality, high performance, and regulatory compliance position it as the ultimate tool for laboratories and manufacturing plants seeking speed, reliability, and security in their operations.

If your company aims to enhance efficiency and compliance in NIR analysis, the Visum Palm GxP is the definitive NIR analyzer for pharmaceutical choice.