Blending process monitoring with in-line NIR spectroscopy

Blending process monitoring with in-line NIR spectroscopy

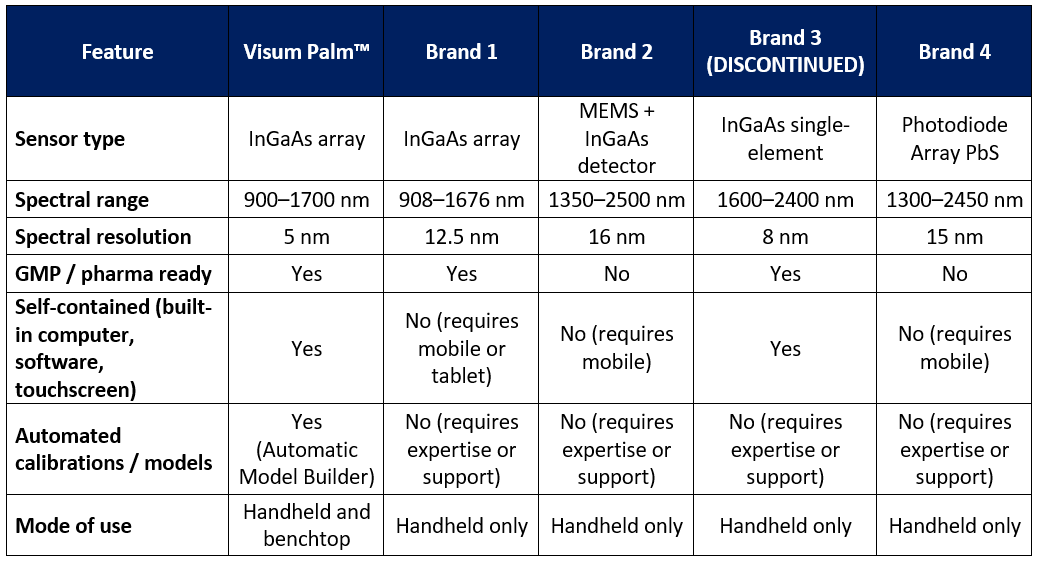

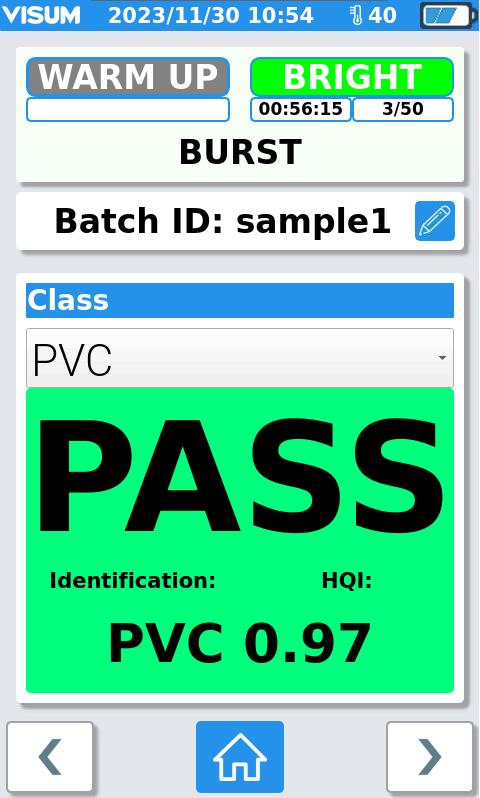

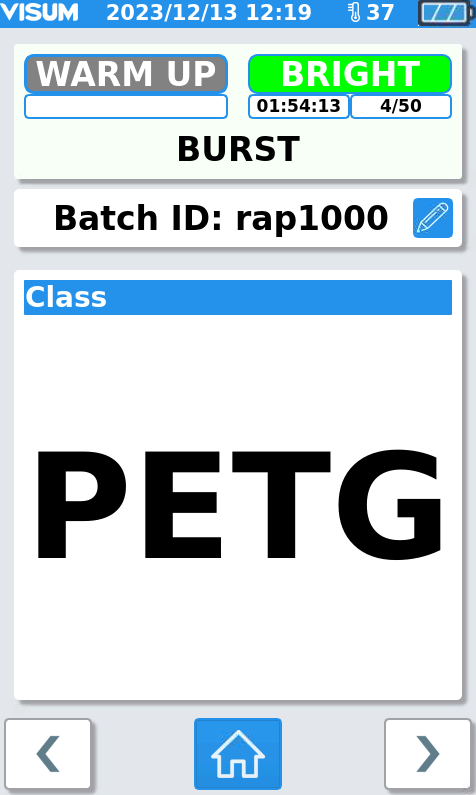

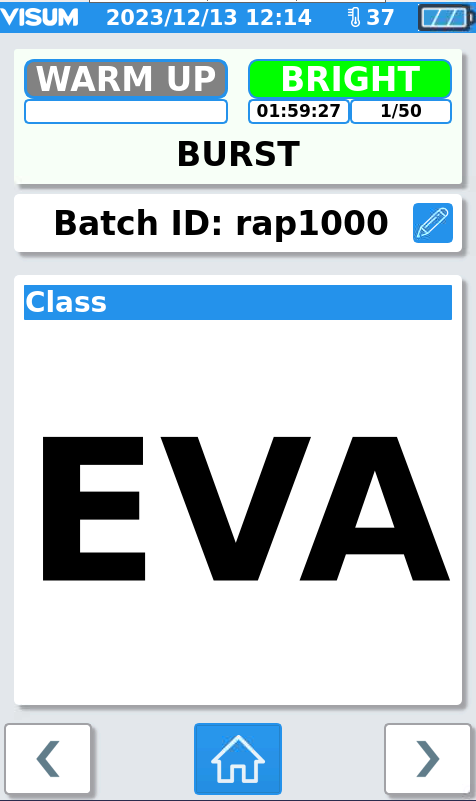

Visum Palm GxP: yeni farmasötik ürünler için NIR analizörü

Visum Palm GxP: yeni farmasötik ürünler için NIR analizörü

Gerçek zamanlı rapamisin izleme için Raman proses analizörü: HPLC ile karşılaştırılabilir sonuçlar

Rapamisin saflaştırmasına uygulanan hat içi Raman proses analizörü

Raman spektroskopisi, gerçek zamanlı ölçümler için bir Raman proses analizörü olarak uygulandığında, farmasötik ve biyoteknolojik üretimde proses kontrolü ve optimizasyonu için güçlü bir teknolojidir. Bu bağlamda, IRIS Technology Solutions (Barselona) tarafından geliştirilen ve üretilen hat içi Raman proses analizörü, kritik bileşiklerin gerçek zamanlı nicelendirilmesi ve proses performansının sürekli izlenmesi için yüksek performanslı bir analitik çözüm olarak öne çıkmaktadır.

Gecikmeli yanıt süreleri, sarf malzemeleri ve yoğun laboratuvar kaynakları gerektiren HPLC gibi geleneksel analitik tekniklerin aksine, bir Raman proses analizörü prosese doğrudan ve gerçek zamanlı bir bakış sağlar. Bu makale, somut bir endüstriyel uygulamayı sunmaktadır: saflaştırma aşamasında rapamisin konsantrasyonunun izlenmesi için Visum Raman In-Line analizörünün kullanımı.

Sonuçlar, at-line konfigürasyonda entegre edilen ve mobil bir rack üzerine monte edilen bu Raman proses analizörünün, offline HPLC analizinin etkin bir şekilde yerini alabileceğini göstermektedir. Uygulama, Almanya’daki farmasötik şirket MyBiotech GmbH ile iş birliği içinde geliştirilmiş olup, PAT stratejileri kapsamında Raman tabanlı proses analitiğinin değerini ortaya koymaktadır.

Rapamisin ekstraksiyon ve saflaştırma prosesi

Rapamisin, organ nakillerinde reddi önlemek amacıyla yaygın olarak kullanılan makrolid bir bileşiktir. Kontrollü substrat beslemesi, sıcaklık ve pH koşulları altında biyoreaktörlerde Streptomyces rapamycinicus kültürü ile fermantasyon yoluyla üretilir. Fermantasyondan sonra rapamisin, organik bir çözücü kullanılarak ekstrakte edilir ve hedef bileşiğin yanı sıra çeşitli yan ürünler içeren karmaşık bir karışım elde edilir.

Bu ekstrakt daha sonra bir kromatografik kolon kullanılarak saflaştırılır; burada rapamisin safsızlıklardan ayrılır ve zenginleştirilmiş fraksiyonlar halinde toplanır. Geleneksel olarak, kolon çıkışından manuel olarak alınan numuneler HPLC ile analiz edilerek hangi fraksiyonların rapamisin içerdiği ve konsantrasyonları belirlenir.

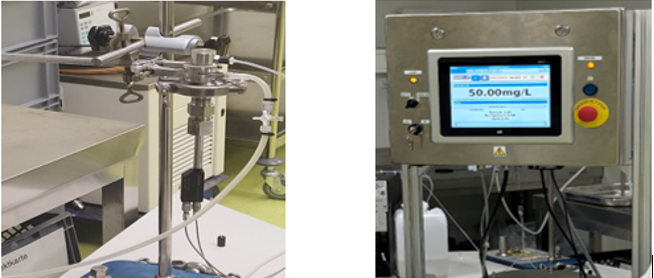

Bu offline iş akışını ortadan kaldırmak için, kromatografik kolon çıkışına özel bir ölçüm haznesi kurulmuştur. Raman proses analizörüne bağlı bir daldırma probu bu hazneye yerleştirilmiş ve rapamisin konsantrasyonunun sürekli ve gerçek zamanlı ölçümü sağlanmıştır. Bu kurulum, fraksiyon toplama, sınıflandırma, çözücü geri dolaşımı veya reddi gibi kararların anında alınmasına olanak tanımış; manuel numune alımıyla ilişkili hataları, gecikmeleri ve kontaminasyon risklerini ortadan kaldırmıştır.

Hat içi Raman proses analizörünün entegrasyonu

Visum Raman In-Line, mobil bir rack üzerinde at-line ortamda yapılandırılmış bir Raman proses analizörü olarak devreye alınmıştır. Bu esnek entegrasyon, analizörün saflaştırma sisteminin hemen yanında çalışmasına olanak tanırken, operatörler için tam erişilebilirlik ve görünürlük sağlamıştır.

Raman probu, kolon çıkışındaki proses akışını sürekli olarak ölçmüş ve rapamisinin varlığı ile konsantrasyonu hakkında gerçek zamanlı geri bildirim sunmuştur. Birkaç saat sürebilen tipik bir ayırma çalışması sırasında, her fraksiyon için çok sayıda Raman ölçümü toplanmış ve HPLC tabanlı analizlere kıyasla çok daha yüksek zamansal çözünürlük elde edilmiştir.

Şekil 1.

Üst: rapamisin saflaştırma sistemi.

Alt sol: ölçüm haznesine yerleştirilmiş Raman probu.

Alt sağ: mobil rack üzerine monte edilmiş Raman proses analizörü ekranı, rapamisin konsantrasyonunu gerçek zamanlı olarak göstermektedir.

Raman proses analizörünün kalibrasyonu ve kemometrik modelleme

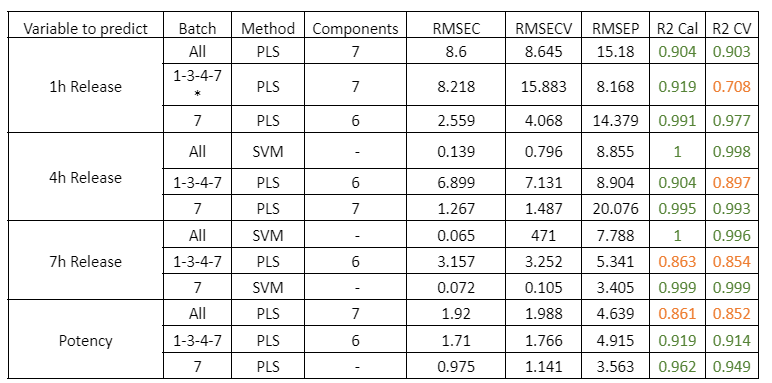

Raman proses analizörünün kalibrasyonu için altı farklı preparat değerlendirilmiştir. Bu preparatlar, rapamisin konsantrasyonları, yan ürün profilleri ve akış hızları açısından geniş bir aralığı kapsayarak gerçekçi proses değişkenliğini sağlamıştır.

Analizör, dakikada üç Raman spektrumu toplayacak ve ortalama değerler raporlayacak şekilde yapılandırılmıştır. Kemometrik model geliştirme için, her bir şişenin doldurulması sırasında kaydedilen tüm Raman spektrumları ortalanarak, her HPLC referans değerine karşılık gelen tek bir temsili spektrum elde edilmiştir.

Spektral verilerin işlenmesi ve nicel modellerin oluşturulması için gelişmiş kemometrik teknikler uygulanmıştır. Gerçekçi bir performans değerlendirmesi sağlamak amacıyla her preparat harici bir doğrulama seti olarak ele alınmıştır. Pratikte, bir preparatı tahmin etmek için kullanılan model, diğer beş preparattan elde edilen verilerle geliştirilmiştir. Bu yaklaşım, altı preparatın tamamı analizör tarafından bağımsız olarak tahmin edilene kadar tekrarlanmıştır.

Raman proses analizöründen elde edilen sonuçlar

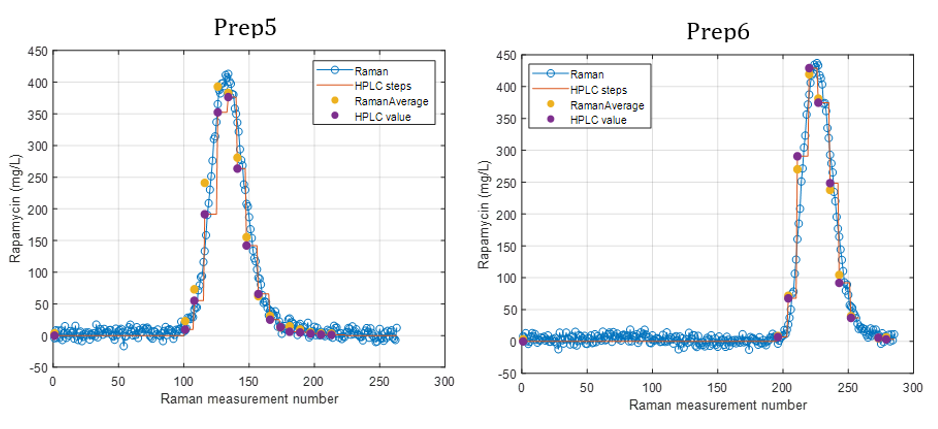

Şekil 2, altı preparat için hat içi Raman proses analizörü ile elde edilen tahmin sonuçlarını göstermektedir. Raman spektroskopisi ile tahmin edilen rapamisin konsantrasyonu eğilimi, HPLC ile ölçülen eğilimi yakından takip etmektedir.

Her bir HPLC veri noktası için üç ila sekiz Raman tahmini mevcuttur. Bu Raman tahminlerinin ortalaması, karşılık gelen HPLC değerleriyle güçlü bir uyum göstermiştir. Preparat 3’te bir sapma gözlemlenmiş olup, bunun ölçüm ile fraksiyon toplama arasındaki zaman farklarından kaynaklanan bir uyumsuzluktan ileri geldiği düşünülmektedir.

Tüm tahmin ve referans değerleri karşılaştırıldığında, analizör 15,7 mg/L gibi düşük bir tahmin hatası ve yüksek bir belirleme katsayısı (R² = 0,98) elde etmiştir. Bu tahmin hatası, yöntemin nicelendirme sınırı ile karşılaştırılabilir düzeydedir.

15 mg/L’nin altındaki rapamisin konsantrasyonlarında Raman tahminleri −15 ile +15 mg/L arasında dalgalanmış ve bu durum modelin pratik algılama sınırını göstermiştir. Doğrulanmış 15–450 mg/L konsantrasyon aralığında ise hat içi Raman proses analizörü, HPLC ile elde edilen sonuçlara son derece benzer, yüksek doğrulukta sonuçlar sunmuştur.

Şekil 2.

Altı preparat için zaman içinde Raman proses analizörü tarafından tahmin edilen rapamisin konsantrasyonu ve HPLC referans verileri.

Raman proses analizi ve PAT uygulamaları için çıkarımlar

Bu çalışma, bir Raman proses analizörünün rapamisin saflaştırmasının gerçek zamanlı izlenmesi için güvenilir ve hassas bir çözüm olduğunu doğrulamaktadır. Visum Raman In-Line, HPLC ile karşılaştırılabilir performansla rapamisinin sürekli nicelendirilmesini sağlamış ve proses verimliliği ile yanıt hızını önemli ölçüde artırmıştır.

Manuel numune alımı ve offline analiz ihtiyacını ortadan kaldıran Visum hat içi Raman proses analizörü, laboratuvar iş yükünü azaltmış, karar verme süreçlerini hızlandırmış ve proses kontrolünü iyileştirmiştir. Bu avantajlar, Raman tabanlı proses analitiğini farmasötik ve biyoteknolojik üretim için özellikle cazip kılmaktadır.

Bu yaklaşım; antikorlar, rekombinant proteinler, aşılar, metabolitler ve diğer aktif farmasötik bileşenler gibi saflaştırma veya formülasyon sırasında gerçek zamanlı nicelendirmeye ihtiyaç duyulan diğer uygulamalara da tamamen aktarılabilir. Daha geniş bir PAT stratejisinin parçası olarak bir Raman proses analizörü, prosese sürekli bir bakış sağlayarak daha yüksek verimlilik, daha iyi kalite kontrolü ve daha sağlam üretim operasyonları sunar.