IRIS Technology presents its solutions at Expoquimia 2023

IRIS Technology presents its solutions at Expoquimia 2023

Forage and feed analysis with NIR spectroscopy

Forage and feed analysis with NIR spectroscopy

Raw material identification and analysis (RMID) using the Visum Palm™ handheld NIR analyser assisted by AI

Raw material identification and analysis (RMID) using the Visum Palm™ handheld NIR analyser assisted by AI

The raw materials identification and analysis (RMID) is a critical process in the pharmaceutical industry because it guarantees the identity and quality of all materials and substances to be used in the manufacturing process to ensure that they meet the specifications that the final products require to reach the consumer with the pharmacological characteristics for which they were designed.

In terms of raw material identification and analysis, both Raman and NIR are complementary techniques and neither represents a final or definitive solution due to the large number of materials, substances and casuistries involved. For example, handheld Raman analysers are sensitive to certain substances that emit fluorescence and are not the appropriate technique for moisture determination (LoD) to replace the Karl Fischer method or for the determination of the average particle size, where NIR spectroscopy is effective and at a lower cost.

Figure 1: Handheld NIR analyser Visum Palm™ handheld or desktop.

Raw material identification and analysis in the pharmaceutical industry

The Visum Palm™ handheld NIR analyser is a self-contained spectrophotometer with embedded computer and touch screen that operates in the 900-1700 nm range useful for the pharmaceutical raw materials identification, verification and classification and has a spectral resolution of 256 pixels, a measuring area of 10 mm in diameter and an illumination area of 50 mm, which allows more chemical information to be obtained from the sample analysed and makes it less sensitive than other spectrophotometers to heterogeneities, even those derived from the particle size for substances that are very similar. The analyser has an illumination system that fires a large amount of light at the sample and a collection system that takes advantage of the larger amount of scattered light due to scattering, which is especially important when working with powdery substances.

Figure 2: Visum Palm™ performing pharmaceutical raw material identification.

Among its particularities, it is the only NIR analyser on the market with AI-assisted software that allows any user, without specific technical knowledge in spectroscopy or multivariate data analysis, to develop their own NIRS libraries and methods and to edit them iteratively according to their needs, for example, to incorporate new substances or to strengthen a class with samples from a new supplier.

The Visum Master™ software in its GMP version has been specifically designed in compliance with the European Medicines Agency “Guideline on the use of near infrared spectroscopy by the pharmaceutical industry and the data requirements for new submissions and variations” (2014) and the Addendum “Defining the Scope of an NIRS Procedure” (2023). It is also compatible with FDA regulation 21 CFR Part 11.

Figure 3: Visum Master™ GMP version software for pharmaceutical users.

Identification, verification and classification

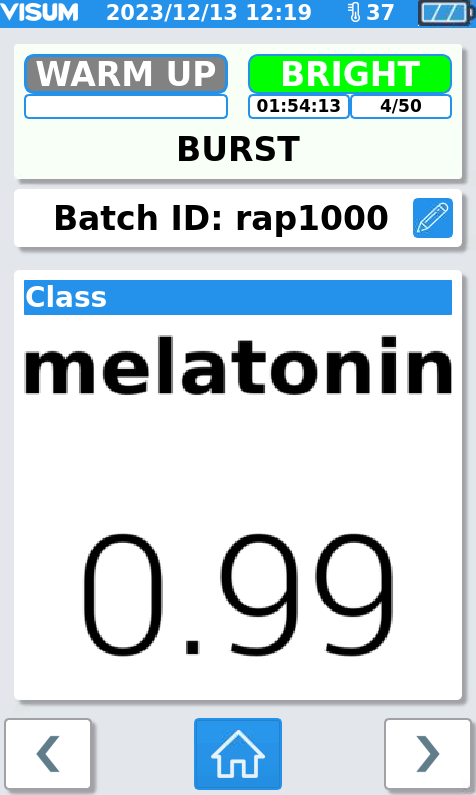

The Visum Palm™ analyser allows the raw material identification or verification analysis of different substances to be carried out in seconds by comparing the spectrum acquired from the sample with the average typical spectrum of each substance in the library. This comparison is made on the basis of a mathematical criterion of similarity, which converts the differences into a numerical value. As a result of the raw material analysis, the Visum Palm™ analyser provides the class with the highest similarity obtained (Figure 3) and lists the other substances in order of highest to lowest similarity.

Unlike the identification analysis, which is agnostic to the material to be inspected, the verification analysis (Figure 4) allows the user to select a specific substance within the library to confirm its identity. The result is either PASS or FAIL and, in the latter case, also indicates the correct and most similar substance.

Figure 4: Raw material identification Figure 5: Verification PASS/FAIL

Classification analysis

In contrast to the above, for feedstock analysis, classification (Figure 5) is a function that uses machine learning algorithms, not similarity algorithms, and allows to properly distinguish (classify) very subtle spectral differences, such as particle size or concentration of a particular analyte, even if they are the same API or excipient. It is a very useful function to identify anomalies in the raw material or to perform a confirmation of the identification analysis in problematic or doubtful cases where the substances are spectrally very similar, thus complementing the identification or verification analysis mentioned above.

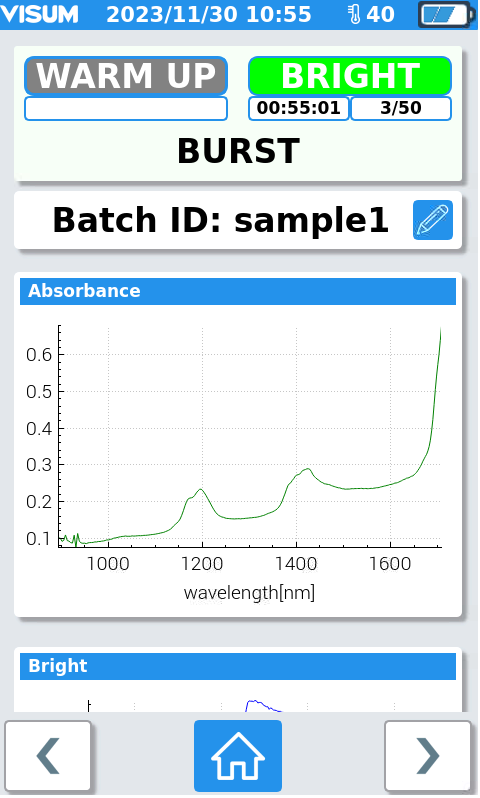

In all the above cases, in addition to the result, the spectrum of the analysed substance is obtained for each measurement (Figure 6).

Figure 6: Classification analysis Figure 7: Spectrum of each measurement

NIRS method generation: advantages of automation for raw material identification and analysis

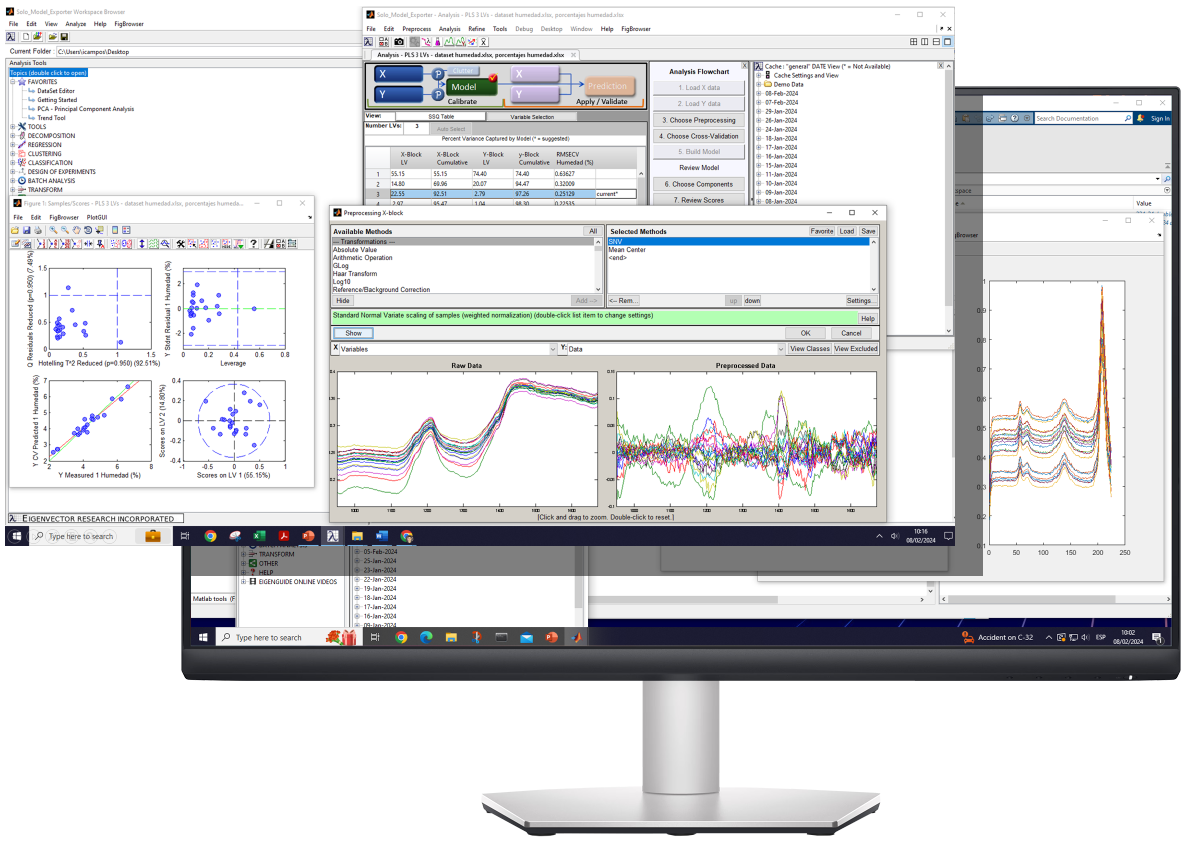

Visum Palm™ is the only NIR analyser on the market that allows end users to develop their own NIRS libraries or methods for identification, classification and quantification without the intermediary of technicians or specialists. Let’s see graphically below how existing market software for multivariate data analysis – or also called chemometrics – for NIRS method development and calibration differs from IRIS Technology Solutions’ Visum Master™ software.

Figure 8: (Left) Chemometrics software for method development and NIRS calibrations. (Right) Development of NIRS methods for identification, classification and quantification with Visum Master™ software.

The above is a graphical example to quickly differentiate how Visum Master™ simplifies a large number of scientific and technological tasks that until now had to be performed by chemometrics experts or specialists during the development phase of a NIRS method. Moreover, the software makes it accessible to any analyst to autonomously perform these tasks and edit the created methods when necessary, making the Visum Palm™ NIR analyser an open system that can cover different analytical needs with proper user training, thus radically changing the accessibility and usability of the NIR technique in the industry.

The Visum Master™ software automatically generates a large number of successive predictive models by applying each time a certain combination of pre-treatments, algorithms and parameterisations. In all cases, it chooses the one with the lowest RMSE and risk of overfitting. It also automatically runs a spectral quality test to identify and remove spectral outliers, i.e. those spectra considered atypical in relation to a predefined range of variation for each class or value, and automatically produces a report of the developed NIRS method with all the technical information on how the model was generated, a document especially useful for external validation of a quantitative NIRS method for release and as supporting documentation for audits.

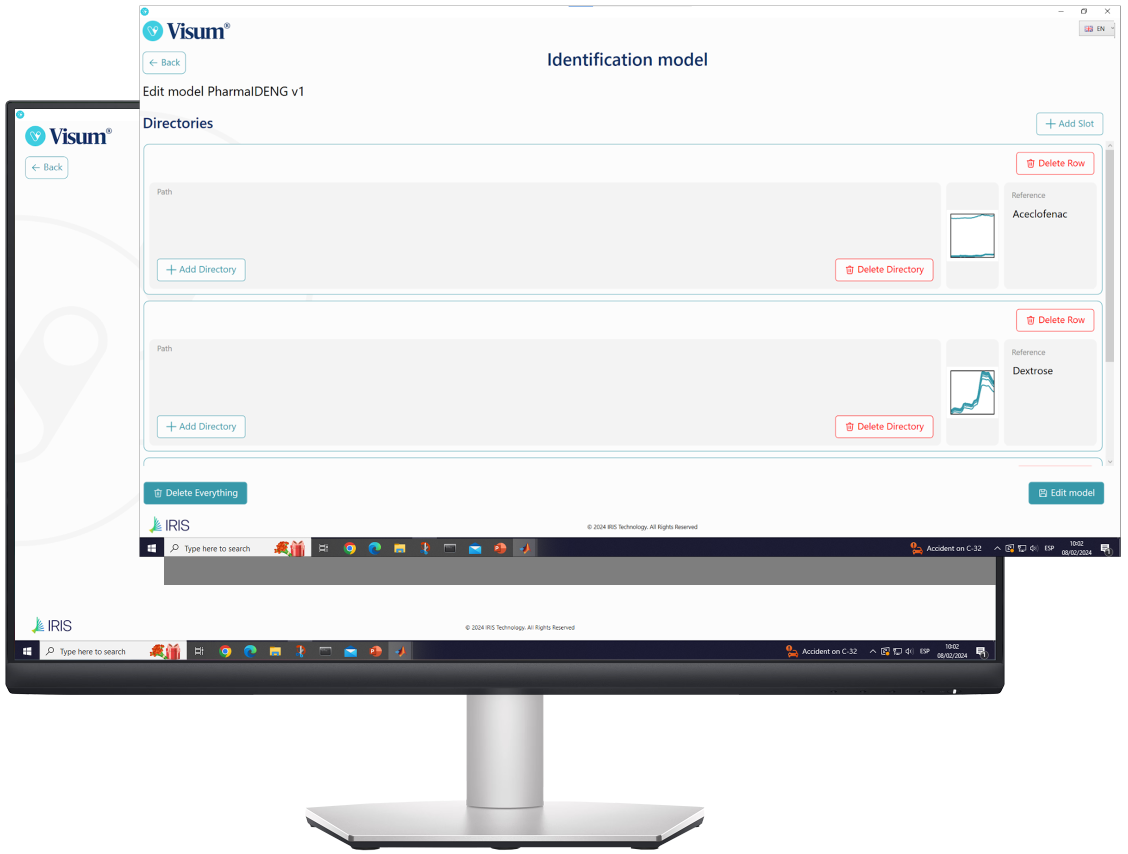

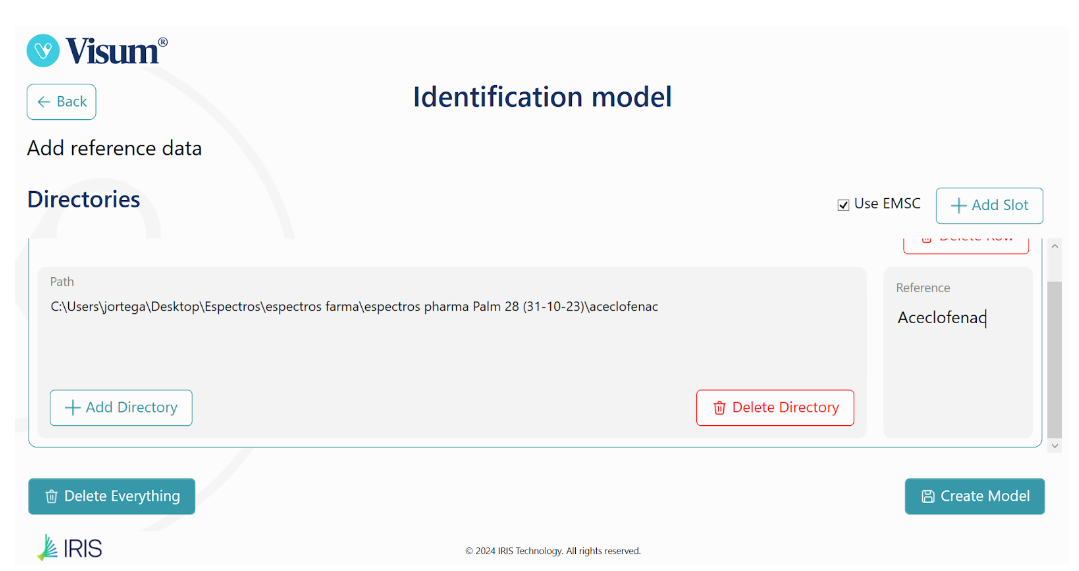

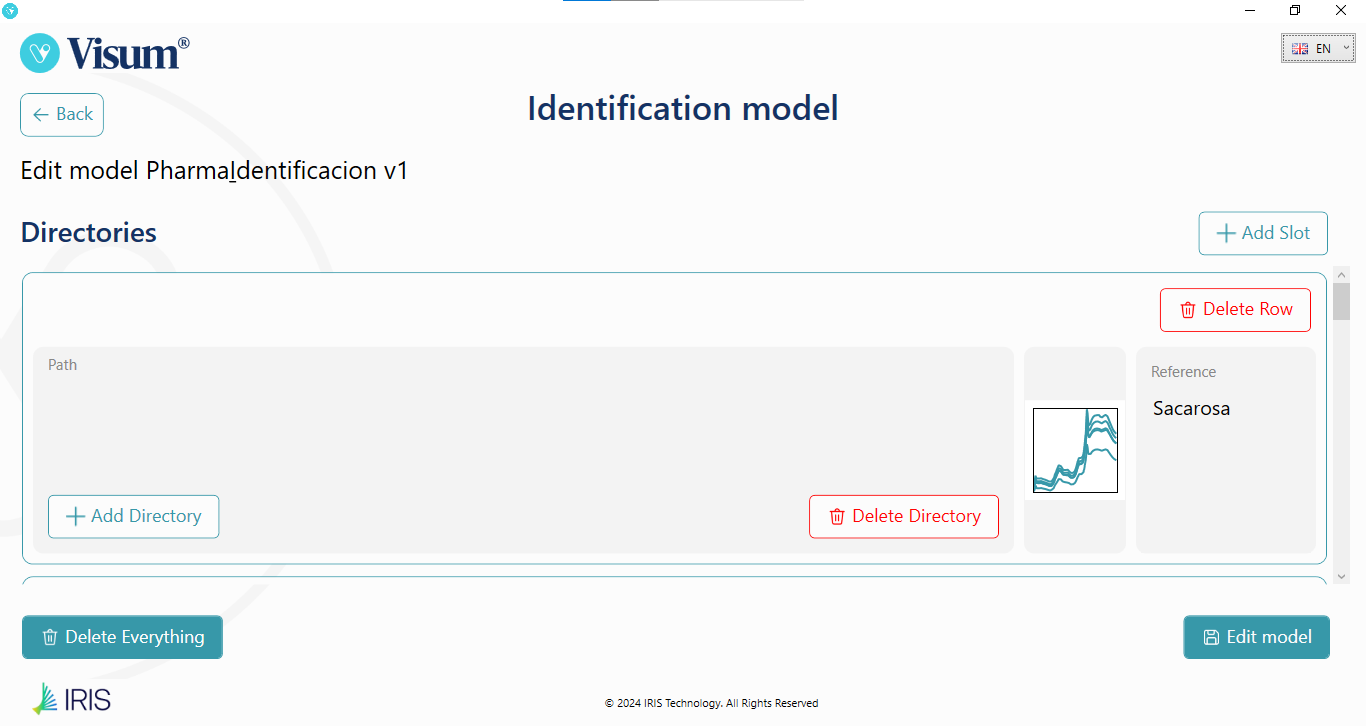

Development and edition of an raw material identification/verification or classification library

To generate a library or identification raw material method for raw material analysis (analogue for classification and quantification), it is only necessary to import the acquired spectra of each substance or calibration sample and enter its reference value, name or class. At the end of the data upload, Visum Master™ will generate the library automatically.

It is also possible to edit and iteratively strengthen the library to incorporate new substances or sample spectra from a new supplier. For each edition, a new version (v1, v2, …) is generated as a backup copy of the changes made. At the end of the process, the NIRS library or methods are exported to the Visum Palm™ portable analyser for use in the routine raw material identification, classification and quantification.

Figure 9: (left)Development of a NIRS raw material identification or classification method or library. (right). Edit raw material identification or classification library. Add new spectra to an existing class or add a new one and its reference (name or class).

Conclusions

Raw material identification and qualification is an essential step in any GMP environment and unlike other technologies, the NIRS technique can identify and classify materials or substances or quantify different analytes of interest, thus reducing the workload in the laboratory or raw material receiving warehouse.

Visum Palm™ offers a unique value unlike any other device on the market in that the creation or editing of NIRS libraries and methods is automated and can be performed without specific knowledge of chemometrics, although it has an “Expert Mode” for advanced users that allows the choice of preprocessing and algorithms during the method generation phase and is activated by licence. It also has the differential of offering automated reports that facilitate the work of any analyst vis-à-vis potential auditors in terms of supporting documentation and external validation of the NIRS method used, even for release.

Visum Palm™ offers the following advantages:

- It is useful for the identification and qualification of materials, including fluorescent materials, which cannot be analysed by Raman spectroscopy.

- In addition to identification raw material analysis it can perform quantitative analysis, e.g. to replace Karl Fischer (LoD) analysis on raw materials.

- It is a self-contained analyser with embedded computer and touch screen and does not require connection to other electronic devices.

- It has a spectral resolution of 3 nm or 256 pixels, a measuring area of 10 mm diameter and a sample illumination area of 50 mm. Its high spectral resolution is very similar to that of laboratory NIRS devices.

- It can be used as a handheld or benchtop analyser.

- It allows customised reports of measurement results in tabular form, comparison of spectra (for raw materials) and incorporation of the company logo.

- It is also capable of automatically generating NIRS libraries or methods and downloading reports for each of them. The Visum Master™ software in its GMP version also allows the possibility to generate the operational qualifications of the device through a guided wizard and an Audit Trail report with all the information about the use of the device in compliance with 21 CFR Part 11.