Sorting and quantification of organic waste

Sorting and quantification of organic waste

IRIS Technology launches “BioWaste Hub”

IRIS Technology launches “BioWaste Hub”

Real-time monitoring of biofuels with NIR spectroscopy

In this post we will discuss NIR spectroscopy monitoring of the bioethanol production process and how on-line NIR is an important ally for real-time monitoring of fermentation results, final quality or purity, process inhibitors and other analytes of interest for the production of high value-added by-products for the industry.

Bioethanol and NIR

Bioethanol is a type of fuel obtained from the fermentation of organic matter rich in sugars and starch, such as corn, sugar beet, sugar cane, among the most popular ones used worldwide. It can even be produced from solid urban waste and biomass with no food value, known as “second generation” bioethanol or lignocellulosic bioethanol, which solves the added problem of giving a productive destination and added value to the organic waste we discard, converting it into biofuel.

As a result of the action of yeasts and enzymes in the fermentation process, and after distillation, bioethanol is obtained for use as biofuel and for blending with fossil fuels. From the rest of the components, by-products are obtained that can change depending on the raw material used in the process, for example, from dry milling, animal feed can be obtained due to its high protein content, or other by-products from wet milling such as corn oil, syrups, to mention a few. Also, from lignocellulosic biomass, by-products can be obtained for reuse in other industries, such as methanol and acetic acid.

Quality control of the bioethanol production process.

Bioethanol quality control is very important to ensure the purity of the product resulting from the process and the valorization of by-products for reuse in other industries. In most biorefineries, the control of reducing sugars (glucose) and ethanol is carried out using analytical techniques offline, i.e. in the laboratory, using high performance liquid chromatography (HPLC), which takes time and resources, or with benchtop NIR spectroscopy, which, unlike HPLC, provides accurate results in just seconds, but is still an unrepresentative and off-line sampling method.

Bioethanol and NIR in line

However, few biorefineries have bet on the introduction of in-line NIR technology to monitor the fermentation process, distillation, the action of process inhibitors or the control of by-products.

In this sense, IRIS Technology has developed several applications for process control in biorefineries using the Visum NIR In-Line ™ analyzer and the portable (handheld) Visum Palm™ NIR.

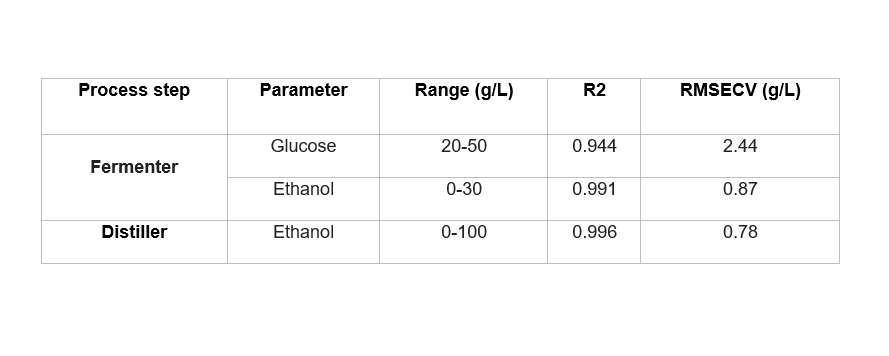

Table 1: Inline glucose and ethanol content prediction using a Visum NIR In-Line ™ analyzer.

Table 1 shows the main parameters, ranges and production stages in the manufacture of lignocellulosic bioethanol at IMECAL‘s Perseo Biotechnology plant, where municipal solid waste is transformed into bioethanol.

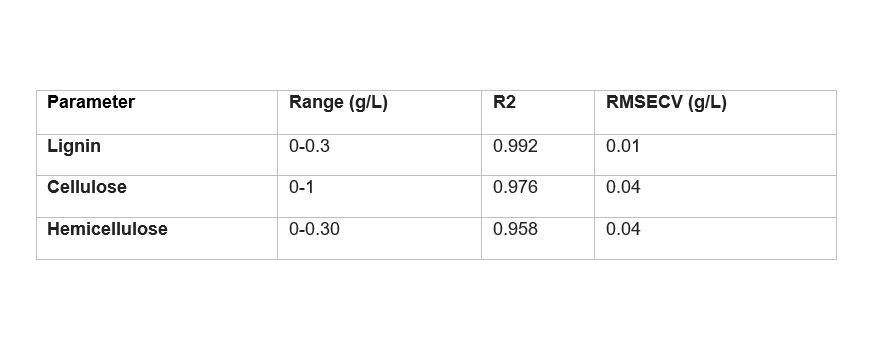

The lignocellulosic biomass delignification process was also monitored to free cellulose from hemicellulose and lignin and thus achieve depolymerization of carbohydrates to produce simple sugars and fermentation to produce ethanol.

Table 2: The pretreatment process consists of a combination of organosolvation with steam explosion (performed by LTU, Lulea Univ. of Technology). Parameters monitored: Lignin, cellulose and hemicellulose content.

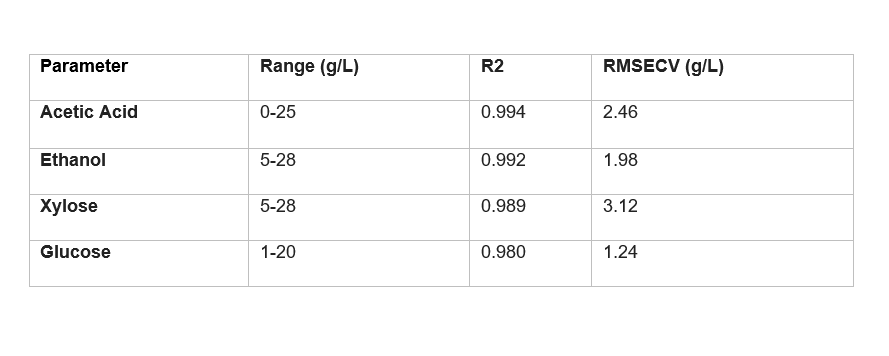

Another application developed in the framework of this project was the monitoring by Visum NIR In-Line ™ of the process of obtaining reducing sugars from hemicellulose present in lignocellulosic residues. In particular, it is shown that it is possible to control inhibiting factors of the fermentation process, such as acetic acid.

Table 3: Parameters monitored: xylose, glucose, acetic acid content.

The installations and tests carried out demonstrate the effectiveness and importance of introducing in-line NIR technology in biorefineries in order to have a more precise control of the different phases of the bioethanol production process, achieve higher quality and therefore increase biofuel efficiency.