Forage and feed analysis with NIR spectroscopy

Forage and feed analysis with NIR spectroscopy

Recycling of multilayer and composite plastics

Recycling of multilayer and composite plastics

NIR Chocolate Analysis: Viscosity and Particle Size in Real-Time

NIR chocolate analysis: NIR spectroscopy applications in chocolate production

In this article we will address real-time NIR chocolate analysis using NIR spectroscopy for the determination of viscosity and particle size, two key product parameters to ensure the highest quality and unique smoothness and taste that make chocolate such a popular food among consumers.

NIR spectroscopy (Near Infrared Spectroscopy) is an analytical technique for determining the chemical composition and certain physical properties of various materials and products based on the analysis of the interaction of optical radiation (light) with the molecular and atomic structures of these materials. NIR is therefore a widespread technique for physical-chemical control in industry, both in laboratory and real-time process analyzers.

In chocolate production, the particle size and composition of the ingredients play a fundamental role in shaping their rheological behavior and sensory perception. The flow properties of chocolate are important because product quality control is a necessity. If the viscosity is too low, the weight of the chocolate on the coated candy will also be too low. When it is too high, bubbles may form inside the chocolate bar. In addition, the taste of the chocolate in the mouth is affected by the viscosity; therefore, the consumer’s tongue may perceive incorrect flow properties. Furthermore, the perceived taste depends on the order and speed of contact, which are related to viscosity and melting speed.

Why does the viscosity have to be right?

- It guarantees the texture, flavor and quality of the chocolate.

- It provides a uniform flow speed (homogeneity), which is very important if there are coatings of nuts, almonds, cookies or others on the chocolate bars.

- Reduces typical defects and processing errors (breaks, cracks and others).

- Mitigates the inherent variability in the line, thus reducing raw material and viscosity modifying ingredients costs.

However, up to now, most of the industry performs a traditional control, either with temperature measurements and adjustments -which we will not discuss in this article-, sampling and laboratory analysis, a viscometer or other monoparametric sensors.

Unlike the above, IRIS Technology’s Visum® process analyzers are multi-parametric and provide the added value of monitoring the entire product flow and reporting directly to the control systems or PLC of the area to generate the necessary corrections in the process, thus ensuring the highest possible homogeneity at all times.

NIR chocolate analysis in the production process

The chocolate production process consists of four main stages: mixing, refining, conching and tempering.

The conching process (dry, plastic and liquid) is one of the most critical and important in chocolate production, where the mixture becomes a fluid liquid and where acidic flavors are eliminated and the cocoa paste is refined to the desired texture and flavor. This structural transition is achieved through the use of thermal and mechanical energy and the incorporation of different ingredients that break up, disintegrate and disperse the large agglomerates until the molten chocolate is obtained.

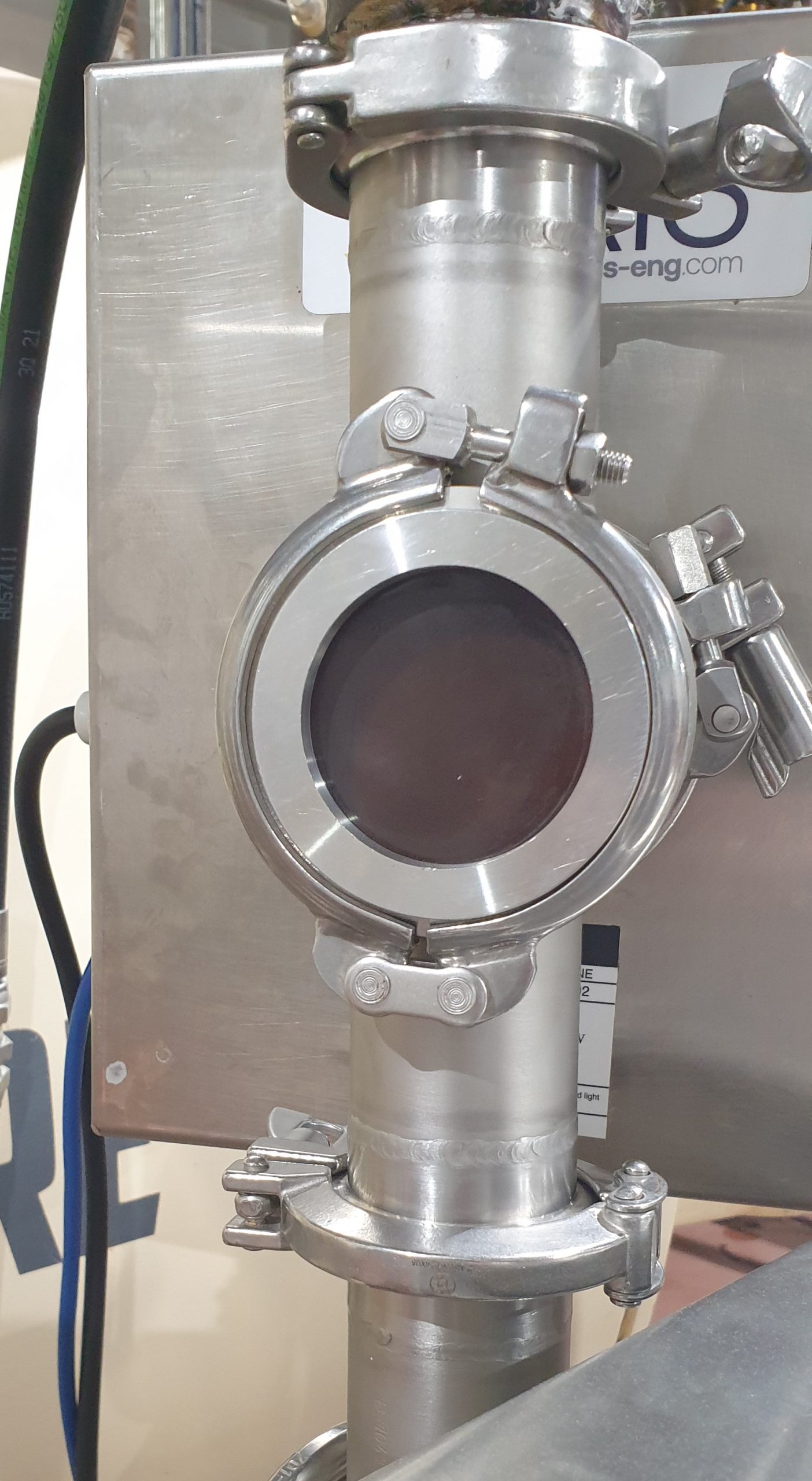

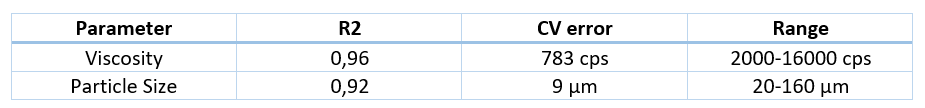

In this process, a Visum NIR In-Line™ multiparametric analyzer was used for the on-line determination of viscosity in the range 2000-16000 cps and where an R2 >0.96 was obtained. In addition, its results were correlated with in-line moisture measurements since an increase in the moisture content of chocolate leads to an increase in its viscosity and an excess of moisture could lead to the formation of sugar agglomerates thus affecting the final texture of the chocolate. NIR is a particularly sensitive method for moisture determination.

Picture 1: Visum NIR In-Line™ Analyser – Conching process monitoring.

While this application was developed on milk chocolate, one would expect that no major differences in compositional changes would be found.

A limitation of the Visum NIR In-Line™ process analyzer is that it does not provide the particle size distribution but the average value resulting from continuous analysis every few seconds. In the case of milk chocolate, a range of 0 to 160 µm was monitored and a correlation coefficient of 0.92 was obtained.

Table 1: Particle size and viscosity with NIR. NIR chocolate analysis

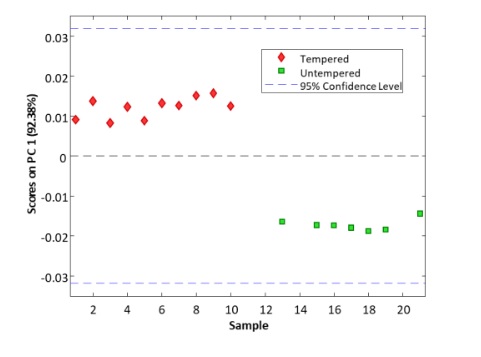

Once the chocolate is properly cooked, it must be tempered and this stage consists of crystallizing a small proportion of the fat, which facilitates its proper solidification after molding. Tempering consists of several stages: first, the chocolate is completely melted (usually at 50⁰C), then cooled to the crystallization point (32-34⁰C), then the temperature is further reduced until crystallization occurs (25-27⁰C) and finally, the chocolate is subjected to a temperature increase to destroy any of the unstable crystals (29-32⁰C). Although a detailed analysis was not performed due to the lack of samples at the different tempering stages and the difficulty of obtaining them for the calibration of the predictive model, the image below validates on-line infrared spectroscopy as a reliable method for the determination of the tempering level.

Figure 1: “Tempered” “Untempered” classification by infrared spectroscopy – Exploratory NIR chocolate analysis.

These tests open a development window to further develop a classificatory and/or quantitative model capable of determining, by means of dedicated machine learning tools, the tempering level of chocolate in real time without having to resort to an offline method such as the temperature meters (tempermeter) commonly used in the industry.

We hope you found this article on new applications of NIR chocolate analysis useful. For further information, we invite you to contact us by email at info@iris-eng.com.