Visum NIR In-Line™ — Industrial NIR Analyzer

Real-time process NIR / FT-NIR analyzer for accurate and continuous measurements in industrial quality control

REQUEST A QUOTEProcess NIR analyzer for real-time monitoring

Visum NIR In-Line™ is an industrial NIR analyzer designed for continuous, real-time measurement of chemical composition directly on the production line. It enables manufacturers to monitor critical quality parameters, detect deviations early, and optimize processes in food, feed, chemical, and pharmaceutical applications. The system supports both NIR and FT-NIR spectral ranges, adapting to a wide variety of products and process conditions.

Turnkey in-line process integration

Visum NIR In-Line™ is a fully self-contained NIR analyzer system with embedded computer, sensor, and software in a single industrial enclosure. It can be integrated directly into existing production lines or process equipment with minimal disruption, supporting fast deployment and reliable long-term operation in industrial and GMP environments. The Visum NIR Inline analyzer supports real-time process monitoring across multiple industries, with a strong focus on food, nutrition and animal feed. It enables continuous control of key parameters such as moisture, protein, fat, fiber, ash, and blend uniformity. In addition, it is widely used in food, grains and cereals, dairy, oils and fats, snacks and bakery, nutraceutical, pharmaceutical, and organic chemical processes to ensure consistent quality, optimize production, and reduce waste.

One NIR analyzer, multiple process integrations

Key Features of the Visum NIR In-Line NIR Analyzer

- Fully self-contained industrial NIR analyzer with embedded computer, sensor, and software.

- Available in NIR (900–1700 nm) and FT-NIR (1100–2500 nm) spectral ranges.

- Filter-free, multiparametric analysis for simultaneous measurement of multiple components.

- Non-destructive, real-time analysis with no sample preparation required.

- NIR analyzer designed for in-line installation on conveyor belts, pipelines, hoppers, reactors, and tanks.

- Compatible with solids, powders, granulates, and liquids.

- Adaptable to different process geometries, surfaces, and product flows.

- Robust industrial design suitable for continuous operation in harsh environments.

NIR Analyzer Applications Across Industrial Sectors

Food & Beverage

- In-line NIR analysis of juices, smoothies, purees, chocolate, dairy products, oils, sweets, olives, nuts, bakery products, baby food, food blends, and nutritional supplements.

- Real-time monitoring of fat, moisture and viscosity during chocolate and confectionery production.

- Continuous determination of Brix, pH-related parameters, and other quality indicators directly on the production line.

- Improved process consistency, reduced waste, and faster quality decisions in food manufacturing.

Pharmaceutical & GMP

- In-line identification and monitoring of raw materials, blends, and intermediates in pharmaceutical manufacturing.

- Real-time control of critical quality attributes (CQAs) during blending, granulation, and drying processes.

- Non-destructive analysis supporting PAT strategies and GMP-compliant environments.

- Suitable for integration into validated processes and controlled production areas.

Animal Feed & Nutrition

- Continuous monitoring of protein, moisture, fat, and fiber in animal feed production.

- In-line control of raw materials, compound feeds, and pellets.

- Early detection of deviations to ensure nutritional consistency and regulatory compliance.

- Optimized formulations and reduced reprocessing in feed manufacturing.

A NIR Analyzer for Other Industries

- Monitoring of polymerization reactions.

- Determination of water content and moisture.

- Fermentation and ethanol monitoring.

- Monitoring of free lacticide during the production of PLA

SENSOR

InGaAs

SPECTRAL RANGE

NIR 900 - 1700 nm / FT-NIR 1100 - 2500 nm (optional)

ANALYZER TYPE

Fully self-contained industrial process NIR analyzer

SPECTRUM ACQUISITION TIME

Configurable from 450 μs

SPECTRAL RESOLUTION (↓ nm = ↑ spectral resolution)

5 nm

ACQUISITION GEOMETRY

Diffuse reflectance, interactance and transflectance according configuration

WEIGHT

∼8,53 kg (Standard) / ∼ 15 Kg (Probe Version)

DIMENSIONS

220x258x230 mm (Standard) 456x387x142 mm (Probe Version)

INGRESS PROTECTION

>IP66

POWER SUPPLY

24VDC. Consumption < 60 W

MATERIAL (ENCLOSURE)

AISI 304

LIGHT SOURCE LIFETIME

1 year (standard use)

BUILT-IN COMPUTER

Quad-core ARMv8®

USER INTERFACE

External-PC-based (for configuration and service tasks) HMI optional

OPERATION MODE

Slave / Continuous

CONNECTION TO THE PROCESS

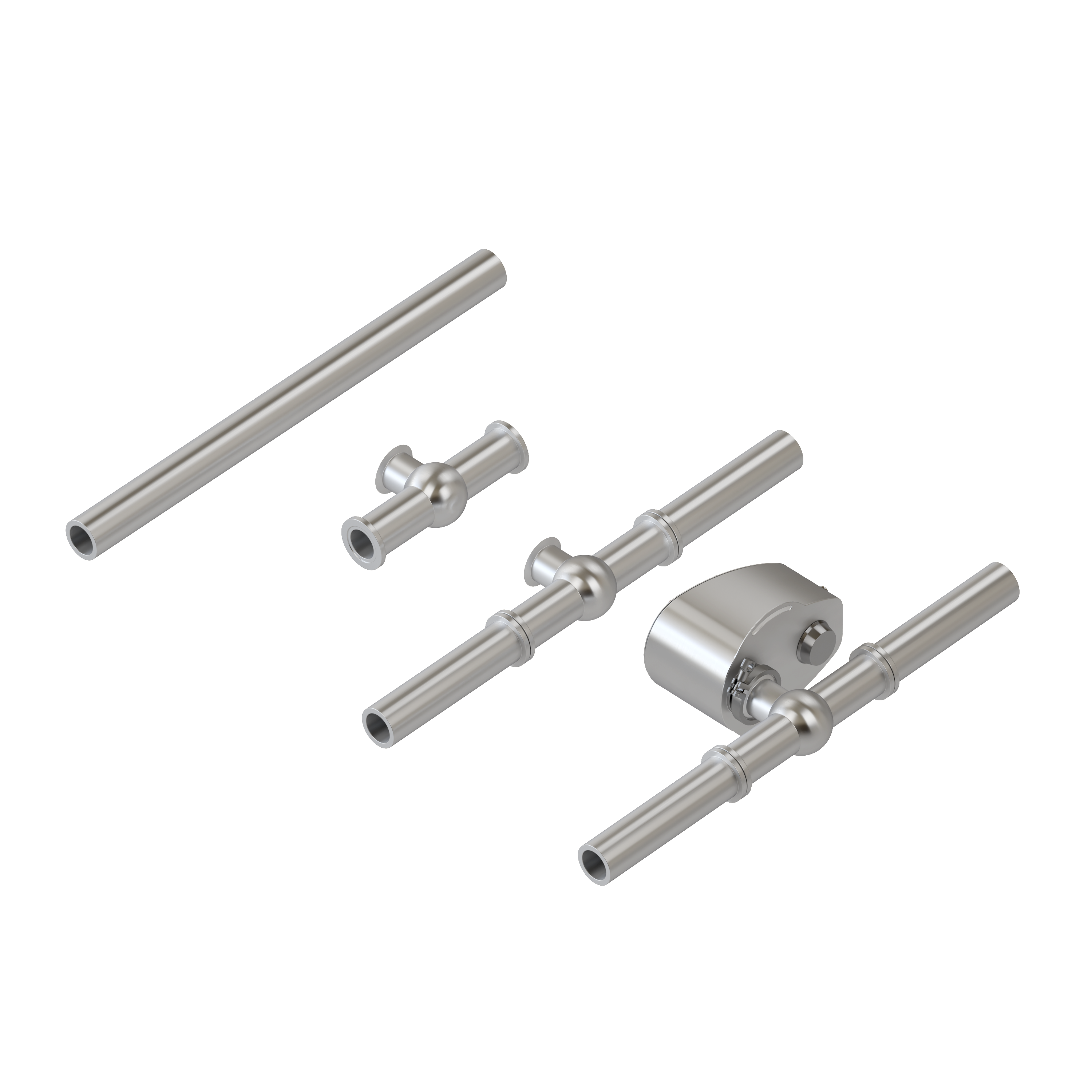

Varinline® DN40–DN80, custom-designed for pipeline installations. Monitoring through a sapphire window module for vessels, reactors, mixers, and dryers. Inspection using an immersion probe (reflectance, transmittance, or transflectance depending on the application)

MAX PRESSURE ON THE WINDOW (PROCESS SIDE)

16 bar (DN40 to DN80) / 10 bar (above DN80). Probe connection up to 100 bar (up to 300 bar with transflectance probe)

MATERIALS (INTERFACE WITH THE PROCESS)

Borosilicate glass and AISI 316L steel (others available)

SOFTWARE EMBEDDED

VISUM®

CALIBRATION SOFTWARE

VISUM MASTER™

CONNECTIVITY

Ethernet / Wi-Fi / Modbus / Profinet / Profibus / OPC-UA & others.