Raw material identification and analysis (RMID) using the Visum Palm™ handheld NIR analyser assisted by AI

Raw material identification and analysis (RMID) using the Visum Palm™ handheld NIR analyser assisted by AI

NIR Chocolate Analyser: Viscosity and Particle Size in Real-Time

NIR Chocolate Analyser: Viscosity and Particle Size in Real-Time

Forage and feed analysis with NIR spectroscopy

Forage and feed analysis with NIR spectroscopy

NIR spectroscopy is a powerful analytical method to determine in real time the chemical composition of a wide variety of materials and mixtures. In this article we will discuss some applications of near infrared spectroscopy ranging from the analysis of forage to the feed analysis, its manufacturing process and finished products for animal feed and nutrition.

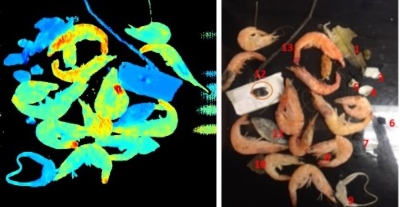

NIR analysis of alfalfa

Alfalfa is a legume that is grown all over the world because of its high protein content and rapid digestibility for animal feed, mainly for livestock. Nowadays, due to the nature of the primary activity itself, various controls are carried out to determine the quality of the product, especially for export to the Chinese and Persian Gulf markets. One of the main parameters determining the quality of alfalfa is crude protein (CP), but other parameters such as acid detergent fibre (ADF) and neutral detergent fibre (NDF) determine the nutritional value of the fodder and the terms of trade in its commercialisation.

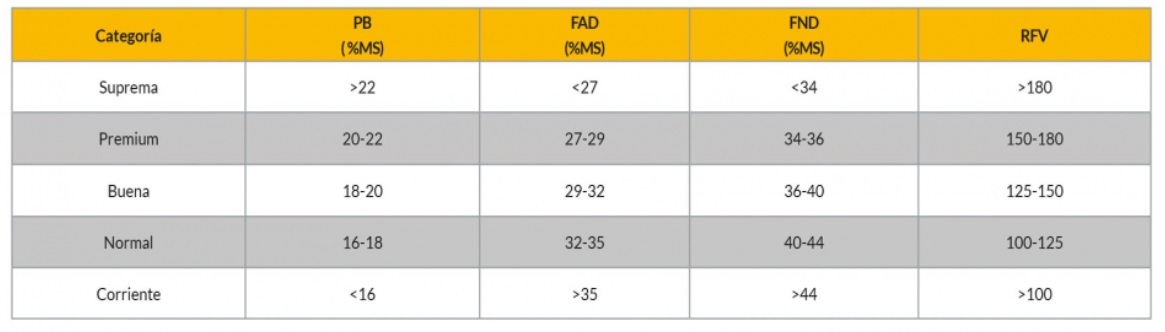

Table 1. Quality of alfalfa (less than 10% grasses) for marketable forage according to USDA Livestock, Hay & Grain Market News (Putnam and Undersander, 2006).

Feed analysis with NIR spectroscopy

NIR spectroscopy and animal nutrition

In conclusion, the use of real-time NIR spectroscopy is becoming more and more widespread in the animal feed sector and particularly in feed analysis, applications which are now extending to the introduction of this technology online for the monitoring of the entire manufacturing process.