Agente Digitalizador Programa Kit Digital

Expediente: SOLI/2024/C032/02637971

Agente Digitalizador Programa Kit Digital

Kit digital

Digitalización para una Nueva Generación de Valor

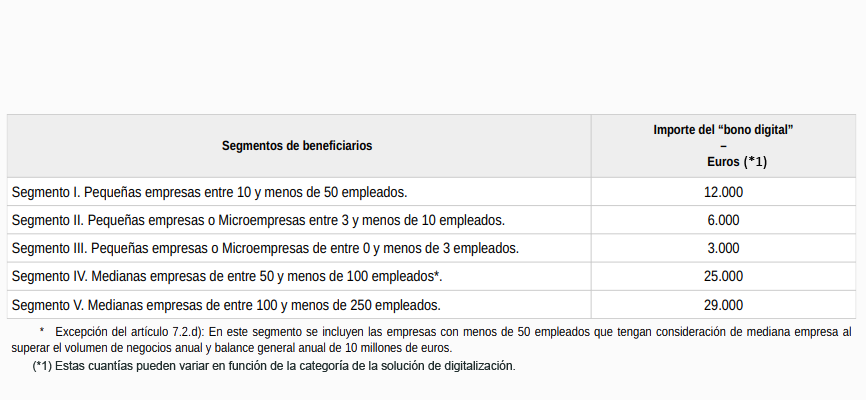

- El Kit Digital es una iniciativa del Gobierno de España, que tiene como objetivo subvencionar la implantación de soluciones digitales disponibles en el mercado para conseguir un avance significativo en el nivel de madurez digital.

Páginas Web / Plataformas Digitales

Desarrollo a Medida

Diseñamos y desarrollamos plataformas digitales personalizadas que se adaptan a las necesidades específicas de tu negocio. Nuestros servicios de desarrollo a medida incluyen:

- Análisis y diseño de requisitos.

- Desarrollo de funcionalidades específicas.

- Integración con sistemas existentes y aplicaciones de terceros.

Plataformas Web y Móviles

Creamos plataformas accesibles desde cualquier dispositivo, optimizadas tanto para web como para móviles. Nuestras soluciones abarcan:

- Diseño responsivo que se adapta a diferentes tamaños de pantalla.

- Aplicaciones móviles nativas para iOS y Android.

- Web apps progresivas (PWA) para una experiencia de usuario fluida.

Marketplaces y Plataformas de Comercio

Creamos marketplaces y plataformas de comercio digital que conectan a vendedores y compradores. Ofrecemos:

- Gestión de múltiples vendedores y productos.

- Pasarelas de pago seguras y confiables.

- Herramientas de análisis y gestión de usuarios.

Gestión de Contenidos (CMS)

Implementamos sistemas de gestión de contenidos que permiten a los usuarios administrar fácilmente el contenido de sus plataformas. Nuestras soluciones CMS incluyen:

- Interfaces intuitivas para la gestión de contenido.

- Capacidades de personalización y escalabilidad.

- Integración con herramientas de marketing y SEO.

Por Qué Elegirnos

- Experiencia y Know-How

Contamos con un equipo de desarrolladores y diseñadores altamente capacitados con experiencia en la creación de plataformas digitales innovadoras. - Enfoque Personalizado

Cada proyecto es único y trabajamos estrechamente con nuestros clientes para asegurar que sus necesidades específicas sean atendidas. - Tecnología de Vanguardia

Utilizamos las tecnologías más recientes y mejores prácticas para desarrollar soluciones robustas y escalables.

Contacta con Nosotros

Si buscas desarrollar una plataforma digital que impulse tu negocio y te permita destacarte en el mercado, ponte en contacto con nosotros. Estamos aquí para convertir tus ideas en realidad y ayudarte a alcanzar tus objetivos digitales.

Aplicaciones de IA

Automatización de Procesos

La inteligencia artificial permite automatizar tareas repetitivas y que consumen mucho tiempo, liberando a tus empleados para que se concentren en actividades de mayor valor añadido. Con nuestras soluciones de automatización de procesos basadas en IA, podrás:

- Optimizar flujos de trabajo.

- Reducir errores humanos.

- Aumentar la eficiencia operativa.

Análisis Predictivo

Anticipa el futuro y toma decisiones más informadas con nuestros servicios de análisis predictivo. Utilizamos algoritmos avanzados de machine learning para analizar grandes volúmenes de datos y proporcionar predicciones precisas sobre tendencias del mercado, comportamiento del cliente, y más. Beneficios:

- Mejor planificación y estrategias de negocio.

- Identificación de oportunidades y riesgos.

- Personalización de ofertas y servicios.

Chatbots y Asistentes Virtuales

Mejora la experiencia de tus clientes con chatbots y asistentes virtuales impulsados por IA. Estos sistemas pueden gestionar consultas en tiempo real, proporcionando respuestas rápidas y precisas. Ofrecemos:

- Soporte 24/7 a clientes.

- Reducción de tiempos de espera.

- Incremento en la satisfacción del cliente.

Reconocimiento de Imágenes y Video

Nuestras soluciones de reconocimiento de imágenes y video basadas en IA pueden transformar la forma en que manejas y analizas contenido visual. Desde la seguridad hasta el marketing, nuestras aplicaciones pueden:

- Identificar y clasificar objetos en tiempo real.

- Mejorar la vigilancia y seguridad.

- Optimizar campañas publicitarias con análisis visual.

Procesamiento de Lenguaje Natural (NLP)

Aprovecha la capacidad de la IA para entender y generar lenguaje humano con nuestras soluciones de procesamiento de lenguaje natural. Ideal para:

- Análisis de sentimiento en redes sociales.

- Mejora en la comprensión y respuesta a textos.

- Automatización de la generación de contenidos.

Por Qué Elegirnos

- Expertos en IA

Nuestro equipo está formado por especialistas con amplia experiencia en el desarrollo e implementación de soluciones de IA. - Soluciones Personalizadas

Adaptamos nuestras aplicaciones a las necesidades específicas de tu negocio. - Resultados Comprobados

Hemos ayudado a numerosas empresas a alcanzar sus objetivos de digitalización y mejorar su rendimiento.

Contacta con Nosotros

Si deseas llevar tu negocio al siguiente nivel con nuestras soluciones de IA, no dudes en contactarnos. Estamos aquí para ayudarte a descubrir el potencial de la inteligencia artificial y aplicarlo de manera efectiva en tu empresa.

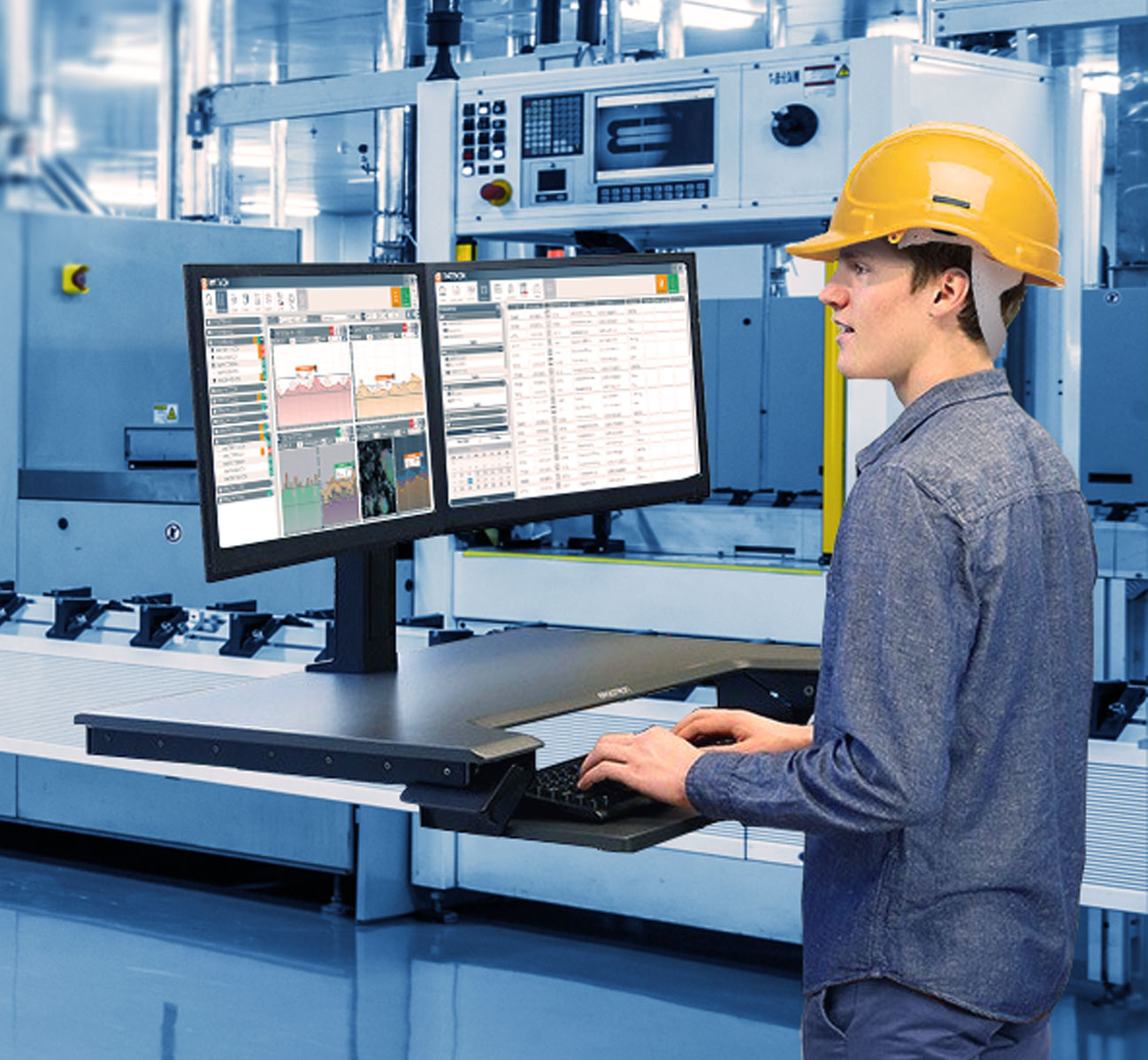

Gestión de procesos

Optimización de Procesos Empresariales

- En un entorno empresarial competitivo, la optimización de procesos es esencial para maximizar la eficiencia y reducir costos. Nuestras soluciones están diseñadas para:

- Analizar y rediseñar flujos de trabajo.

- Eliminar ineficiencias y cuellos de botella.

- Mejorar la productividad y la calidad.

Automatización de Tareas

La automatización de tareas rutinarias y repetitivas permite que tu equipo se concentre en actividades estratégicas. Con nuestras herramientas de automatización de procesos:

- Reducirás el tiempo dedicado a tareas manuales.

- Aumentarás la precisión y consistencia.

- Mejorarás la moral y satisfacción de los empleados.

Gestión Documental

La gestión eficaz de documentos es clave para cualquier organización. Nuestras soluciones te permiten:

- Digitalizar y almacenar documentos de forma segura.

- Acceder a la información de manera rápida y sencilla.

- Cumplir con las normativas y estándares de seguridad.

Control de Calidad

Implementamos sistemas de gestión de procesos que aseguran la calidad en cada etapa de producción. Con nuestro enfoque en el control de calidad:

- Identificarás y corregirás errores rápidamente.

- Mantendrás altos estándares de producción.

- Mejorarás la satisfacción del cliente y la reputación de tu marca.

Análisis de Datos y Reportes

La toma de decisiones basada en datos es crucial para el éxito empresarial. Nuestras soluciones de análisis de datos te proporcionan:

- Informes detallados y personalizados.

- Análisis en tiempo real para decisiones informadas.

- Identificación de tendencias y patrones para mejorar procesos.

Por Qué Elegirnos

- Experiencia Comprobada

Contamos con una trayectoria sólida en la implementación de soluciones de gestión de procesos en diversas industrias. - Tecnología Avanzada

Utilizamos herramientas y tecnologías de vanguardia para garantizar los mejores resultados. - Enfoque Personalizado

Nos adaptamos a las necesidades específicas de tu negocio, asegurando soluciones a medida.

Contacta con Nosotros

Si deseas optimizar la gestión de procesos en tu empresa y alcanzar nuevos niveles de eficiencia y productividad, ponte en contacto con nosotros. Estamos aquí para ayudarte a transformar tus operaciones y mejorar tu rendimiento empresarial.

Comercio electrónico

Desarrollo de Tiendas Online

Creamos tiendas online a medida que ofrecen una experiencia de compra excepcional. Nuestro enfoque en el desarrollo de comercio electrónico incluye:

- Diseño atractivo y fácil de usar.

- Integración con múltiples plataformas de pago.

- Funcionalidades avanzadas como carrito de compras, gestión de inventario y seguimiento de pedidos.

Optimización para Motores de Búsqueda (SEO)

Mejoramos la visibilidad de tu tienda online en los motores de búsqueda para atraer más tráfico orgánico. Nuestras estrategias de SEO incluyen:

- Investigación de palabras clave y optimización de contenido.

- Mejora de la velocidad y rendimiento del sitio.

- Construcción de enlaces y estrategias de marketing de contenidos.

Marketing Digital

Impulsamos tus ventas online mediante estrategias de marketing digital efectivas. Nuestros servicios incluyen:

- Gestión de campañas publicitarias en Google Ads y redes sociales.

- Marketing por correo electrónico y automatización de marketing.

- Análisis y optimización continua de campañas para maximizar el retorno de inversión.

Experiencia de Usuario (UX)

Diseñamos experiencias de usuario intuitivas y atractivas que convierten visitantes en clientes. Nuestro enfoque en UX incluye:

- Navegación fácil y lógica.

- Proceso de pago simplificado y seguro.

- Personalización de la experiencia de compra.

Por Qué Elegirnos

- Expertos en E-commerce

Nuestro equipo tiene amplia experiencia en el desarrollo y optimización de tiendas online. - Soluciones Integrales

Ofrecemos un enfoque completo que abarca desde el desarrollo del sitio hasta el marketing y la gestión de inventario. - Resultados Medibles

Nos enfocamos en lograr resultados tangibles que impulsen tu crecimiento y éxito en el comercio electrónico.

Contacta con Nosotros

Si estás listo para llevar tu negocio al mundo digital y aumentar tus ventas a través de una tienda online optimizada y eficiente, contáctanos. Estamos aquí para ayudarte a construir y escalar tu presencia en el comercio electrónico.

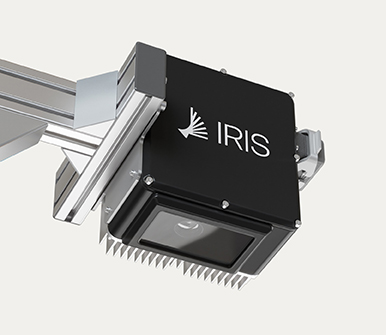

Nuestras Soluciones de Ingeniería de Software

Soluciones Digitales Llave en Mano para la Industria

LO QUE NUESTROS CLIENTES DICEN DE IRIS