Digitising Agent Digital Kit Programme

EXPEDIENT: SOLI/2024/C032/02637971

Digitising Agent Digital Kit Programme

KIT DIGITAL

Digitalisation for New Value Generation

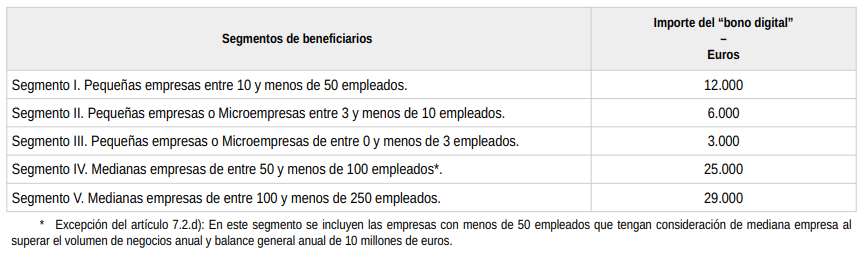

- The Digital Kit is an initiative of the Spanish Government, which aims to subsidise the implementation of digital solutions available on the market in order to achieve a significant advance in the level of digital maturity.

Websites / Digital Platforms

Tailor-made development

We design and develop customised digital platforms that are tailored to the specific needs of your business. Our custom development services include:

- Requirements analysis and design.

- Development of specific functionalities.

- Integration with existing systems and third party applications.

Web and Mobile Platforms

We create platforms accessible from any device, optimised for both web and mobile. Our solutions include:

- Responsive design that adapts to different screen sizes.

- Native mobile apps for iOS and Android.

- Progressive Web Apps (PWA) for a smooth user experience.

Marketplaces and Commerce Platforms

We create marketplaces and digital commerce platforms that connect sellers and buyers. We offer:

- Management of multiple sellers and products.

- Secure and reliable payment gateways.

- Analytics and user management tools.

Content Management Systems (CMS)

We implement content management systems that allow users to easily manage content on their platforms. Our CMS solutions include:

- Intuitive interfaces for content management.

- Customisation and scalability capabilities.

- Integration with marketing and SEO tools.

WHY CHOOSE US

- EXPERIENCE AND KNOW-HOW

We have a team of highly skilled developers and designers with experience in creating innovative digital platforms.

- CUSTOMISED APPROACH

Each project is unique and we work closely with our clients to ensure that their specific needs are met.

- CUTTING-EDGE TECHNOLOGY

We use the latest technologies and best practices to develop robust and scalable solutions.

CONTACT US

If you are looking to develop a digital platform that will boost your business and allow you to stand out in the market, get in touch with us. We are here to turn your ideas into reality and help you achieve your digital goals.

AI applications

PROCESS AUTOMATION

Artificial intelligence allows you to automate repetitive and time-consuming tasks, freeing your employees to focus on higher value-added activities. With our AI-based process automation solutions, you can:

- Optimise workflows.

- Reduce human error.

- Increase operational efficiency.

PREDICTIVE ANALYTICS

Anticipate the future and make more informed decisions with our predictive analytics services. We use advanced machine learning algorithms to analyse large volumes of data and provide accurate predictions on market trends, customer behaviour, and more. Benefits:

- Better business planning and strategies.

- Identification of opportunities and risks.

- Personalisation of offers and services.

CHATBOTS AND VIRTUAL ASSISTANTS

Improve your customers’ experience with AI-powered chatbots and virtual assistants. These systems can handle real-time queries, providing fast and accurate responses. We offer:

- 24/7 customer support.

- Reduced waiting times.

- Increased customer satisfaction.

IMAGE AND VIDEO RECOGNITION

Our AI-based image and video recognition solutions can transform the way you manage and analyse visual content. From security to marketing, our applications can:

- Identify and classify objects in real time.

- Improve surveillance and security.

- Optimise advertising campaigns with visual analytics.

NATURAL LANGUAGE PROCESSING (NLP)

Harness AI’s ability to understand and generate human language with our natural language processing solutions. Ideal for:

- Sentiment analysis in social networks.

- Improved text comprehension and response.

- Automating content generation.

WHY CHOOSE US

- AI EXPERTS

Our team is made up of specialists with extensive experience in the development and implementation of AI solutions.

- CUSTOMISED SOLUTIONS

We tailor our applications to the specific needs of your business.

- PROVEN RESULTS

We have helped numerous companies achieve their digitisation goals and improve their performance.

CONTACT US

If you want to take your business to the next level with our AI solutions, don’t hesitate to contact us. We are here to help you discover the potential of artificial intelligence and apply it effectively in your business.

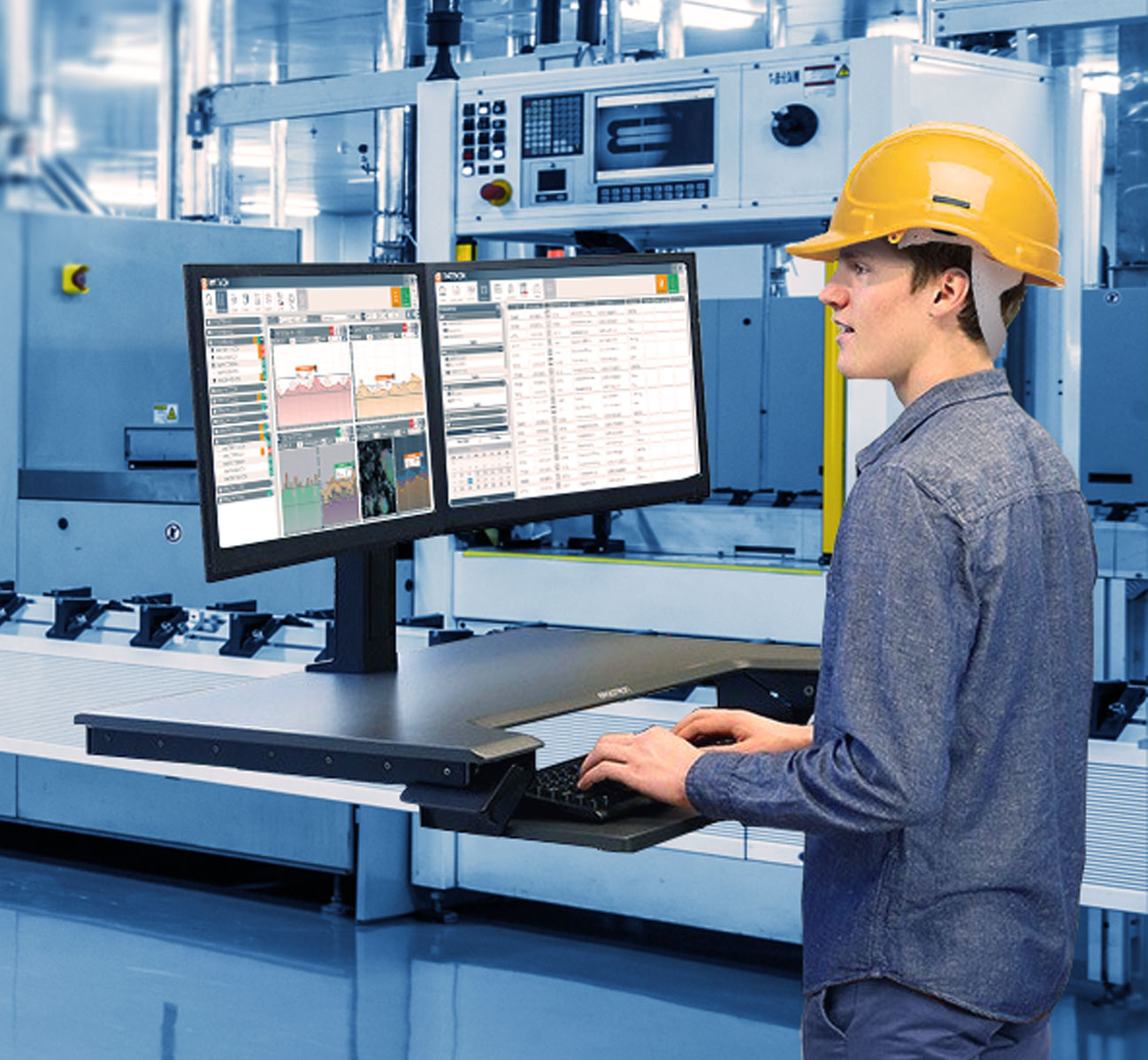

Process management

BUSINESS PROCESS OPTIMISATION

In a competitive business environment, process optimisation is essential to maximise efficiency and reduce costs. Our solutions are designed to:

- Analyse and redesign workflows.

- Eliminate inefficiencies and bottlenecks.

- Improve productivity and quality.

TASK AUTOMATION

Automating routine and repetitive tasks allows your team to focus on strategic activities. With our process automation tools:

- You will reduce time spent on manual tasks.

- Increase accuracy and consistency.

- Improve employee morale and satisfaction.

DOCUMENT MANAGEMENT

Effective document management is key to any organisation. Our solutions allow you to:

- Securely digitise and store documents.

- Access information quickly and easily.

- Comply with regulations and security standards.

QUALITY CONTROL

We implement process management systems that ensure quality at every stage of production. With our focus on quality control:

- You’ll identify and correct errors quickly.

- Maintain high production standards.

- Improve customer satisfaction and brand reputation.

DATA ANALYSIS AND REPORTING

Data-driven decision making is crucial to business success. Our data analytics solutions provide you with:

- Detailed, customised reports.

- Real-time analysis for informed decisions.

- Identification of trends and patterns to improve processes.

WHY CHOOSE US

- PROVEN EXPERIENCE

We have a strong track record of implementing process management solutions in a variety of industries.

- ADVANCED TECHNOLOGY

We use state-of-the-art tools and technologies to ensure the best results.

- CUSTOMISED APPROACH

We adapt to the specific needs of your business, ensuring tailor-made solutions.

CONTACT US

If you want to optimise process management in your company and reach new levels of efficiency and productivity, contact us. We are here to help you transform your operations and improve your business performance.

E-commerce

ONLINE SHOP DEVELOPMENT

We create bespoke online shops that offer an exceptional shopping experience. Our approach to e-commerce development includes:

- Attractive and user-friendly design.

- Integration with multiple payment platforms.

- Advanced features such as shopping cart, inventory management and order tracking.

SEARCH ENGINE OPTIMISATION (SEO)

We improve the visibility of your online shop in search engines to attract more organic traffic. Our SEO strategies include:

- Keyword research and content optimisation.

- Improving site speed and performance.

- Link building and content marketing strategies.

DIGITAL MARKETING

We boost your online sales through effective digital marketing strategies. Our services include:

- Google Ads and social media campaign management.

- Email marketing and marketing automation.

- Ongoing campaign analysis and optimisation to maximise ROI.

USER EXPERIENCE (UX)

We design intuitive and engaging user experiences that convert visitors into customers. Our UX approach includes:

- Easy and logical navigation.

- Simplified and secure checkout process.

- Personalisation of the shopping experience.

WHY CHOOSE US

- E-COMMERCE EXPERTS

Our team has extensive experience in the development and optimisation of online shops.

- END-TO-END SOLUTIONS

We offer a complete approach from site development to marketing and inventory management.

- MEASURABLE RESULTS

We focus on achieving tangible results that drive your e-commerce growth and success.

CONTACT US

If you’re ready to take your business digital and increase your sales through an optimised and efficient online shop, contact us. We are here to help you build and scale your e-commerce presence.

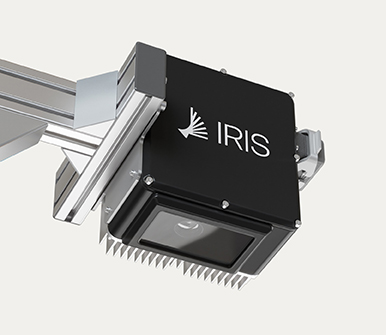

Our Solutions

Turnkey digital solutions for industry

COSA DICONO I NOSTRI CLIENTI SULLA IRIS