Visum NIR In-Line™ - In-line NIR analyzer

Real-time process NIR analyzer: accurate and continuous measurements for process optimisation and quality control in the plant.

REQUEST A QUOTEProcess NIR analyzer for real-time monitoring

Visum NIR In-Line™ is a versatile and accurate process NIR analyzer for real-time chemical composition analysis in production lines. It adapts to different geometries and types of installations (conveyor belt, pipeline, tank). It can also be integrated into process machinery (e.g. blenders and dryers).

Turnkey solutions

Installation of the Visum NIR In-Line™ process analyzer is fast and minimally invasive. As manufacturers and engineering we can adapt to different needs in terms of operating environment, inspection surface and calibrate the device according to the measurement needs. The Visum NIR In-Line™ analyzer has an embedded computer, network connection and Wi-Fi. Among its most popular applications are blending end-point monitoring, drying end-point monitoring, moisture in different bulk products and real-time brix analysis in fruits and derivatives, among many other applications to analyze different parameters and products in numerous industries.

Same NIR analyzer for multiple solutions

Main features

- Embedded computer, stand-alone NIR analyzer device.

- Spectral range from 900 nm to 1700 nm. NIR analyzer without filters and multiparametric.

- Non-destructive analysis without sample preparation.

- Adaptability to different surfaces and monitoring needs.

- Multiple communication drivers with information systems.

- Connectivity via network cable or Wi-Fi.

- Quick to install and calibrate.

- Software Visum® for control, visualisation and configuration needs.

Sectors

Food

- Food analysis: juices, smoothies, purees, chocolate, dairy products, oils, sweets, olives, nuts, bakery products, baby food, blends, food supplements, among other foods and beverages.

- Fat, moisture, viscosity and particle size in chocolate production.

- pH and Brix dregree determination in real time.

- Analysis of raw materials and bulk products.

- Grain analysis.

- Determination of homogeneity of blends in real time.

Pharma

- Determination of uniformity and homogeneity of content (% APIs and excipients).

- Automatic determination of blending and drying end point.

- Quantitative analysis.

Other industries

- Monitoring of polymerization reactions.

- Determination of water content and moisture.

- Fermentation and ethanol monitoring.

- Monitoring of free lacticide during the production of PLA

SENSOR

InGaAs

SPECTRAL RANGE

900 - 1700 nm

SPECTRUM ACQUISITION TIME

Configurable from 450 μs

SPECTRAL RESOLUTION (↓ nm = ↑ spectral resolution)

3 nm

ACQUISITION GEOMETRY

Diffuse reflectance, interactance and transflectance

WEIGHT

8,53 kg

DIMENSIONS

220x258x230 mm3

Ingress protection

IP66

POWER SUPPLY

24VDC. Consumption < 60 W

MATERIAL (ENCLOSURE)

AISI 304

LIGHT SOURCE LIFETIME

1 year (standard use)

BUILT-IN COMPUTER

Quad-core ARMv8®

USER INTERFACE

External-PC-based (for configuration and service tasks) HMI optional

OPERATION MODE

Slave / Continuous

CONNECTION TO THE PROCESS

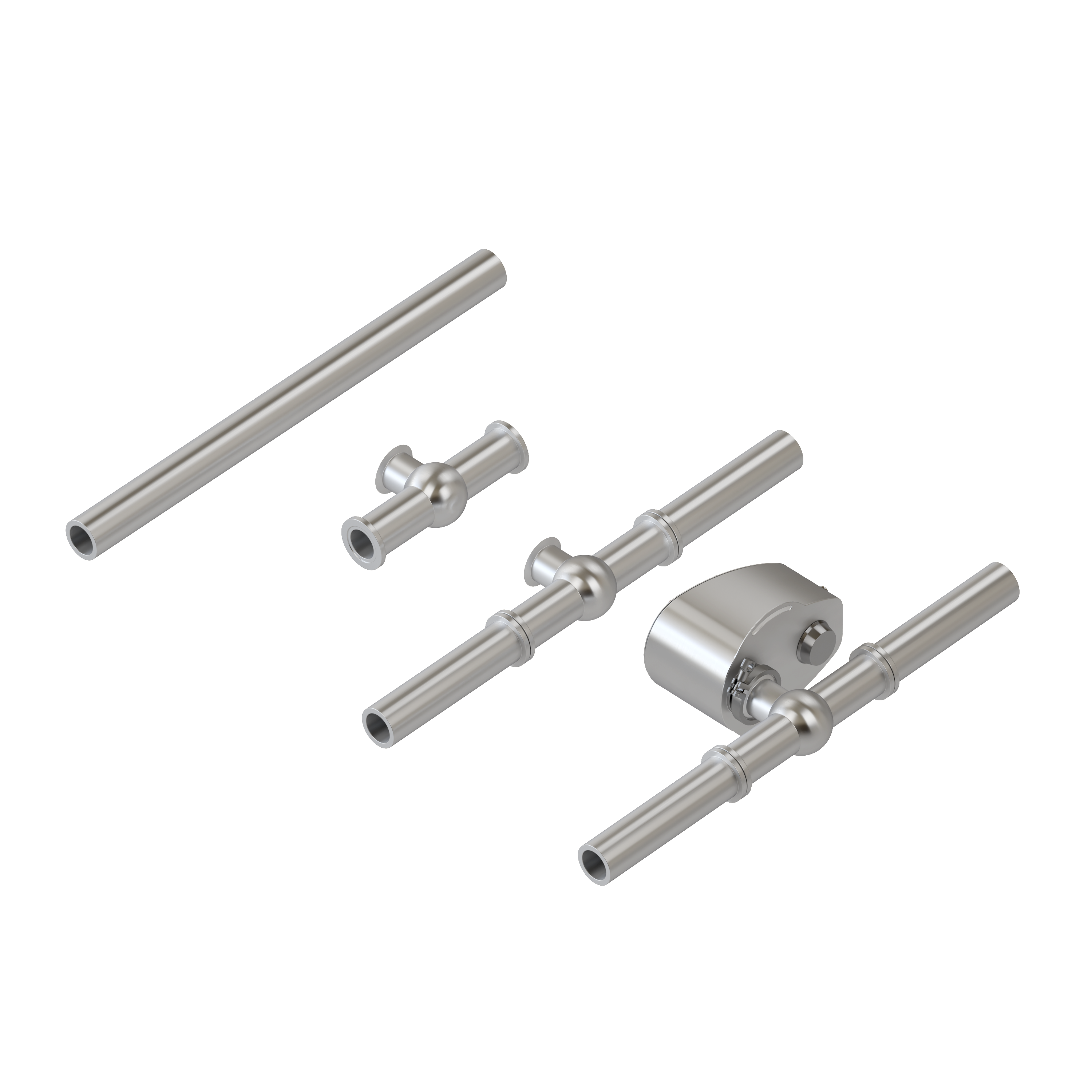

DN40 to DN80. Varinline ®. Larger diameters on request / Ad-hoc inspection probes.

MAX PRESSURE ON THE WINDOW (PROCESS SIDE)

16 bar

MATERIALS (INTERFACE WITH THE PROCESS)

Borosilicate glass and AISI 316L steel

SOFTWARE EMBEDDED

VISUM®

CALIBRATION SOFTWARE

VISUM MASTER™

CONNECTIVITY

Ethernet / Wi-Fi / Modbus / Profinet / Profibus / OPC-UA & others..